Die casting is a sophisticated manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method is widely regarded for its ability to produce complex shapes with excellent dimensional accuracy and a smooth surface finish. The die casting steps can be broken down into several key phases:

Mold Design:The initial step in the die casting process is designing the mold. This involves collaboration between our engineers and clients to ensure that the mold meets the precise specifications required for the final product. The design phase considers factors such as material flow, cooling rates, and parting lines to optimize production efficiency.

Material Selection:Choosing the right material is critical for the success of the die casting process. At Shenzhen Jingrui, we work with a variety of materials, including aluminum alloys, zinc, and magnesium. Each material offers unique properties, such as weight reduction and corrosion resistance, making them suitable for different applications.

Melting and Injection:Once the mold is ready and the material is selected, the metal is melted in a furnace. The molten metal is then injected into the mold at high pressure, ensuring that it fills every cavity. This step is crucial for achieving the desired shape and properties of the final product.

Cooling and Solidification:After the molten metal fills the mold, it is allowed to cool and solidify. The cooling time can vary depending on the material and part thickness. Proper cooling is essential to avoid defects and ensure the integrity of the casting.

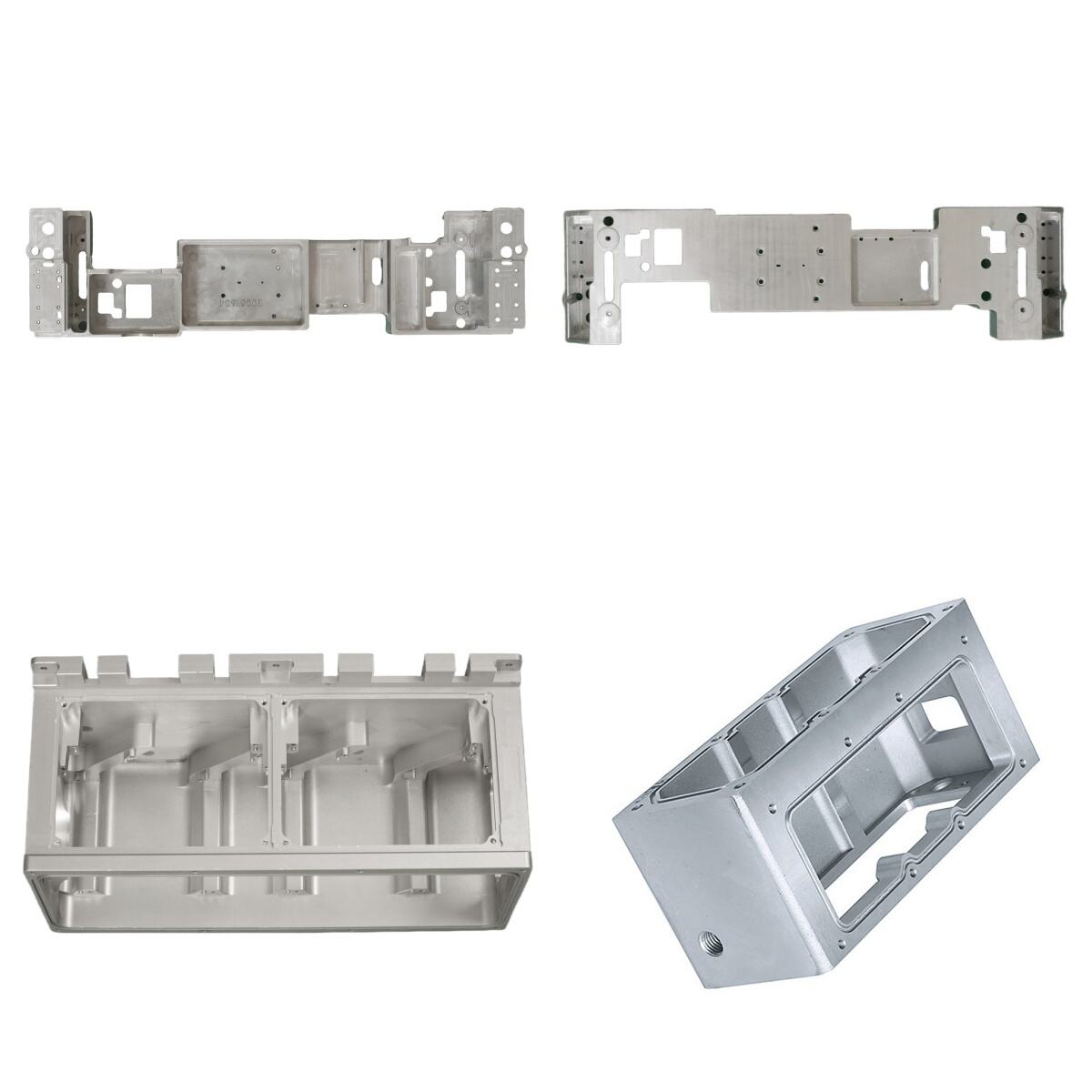

Ejection and Finishing:Once the metal has solidified, the mold opens, and the casting is ejected. The final step involves finishing processes such as machining, surface treatment, and quality inspection. These processes ensure that the product meets all specifications and is ready for use in its intended application.

The die casting steps we employ at Shenzhen Jingrui Precision Technology Co., Ltd. are designed to maximize efficiency while maintaining the highest standards of quality. Our experienced team continually monitors each phase of production, ensuring that we deliver exceptional metal parts to our clients across various industries, including automotive, aerospace, and construction.