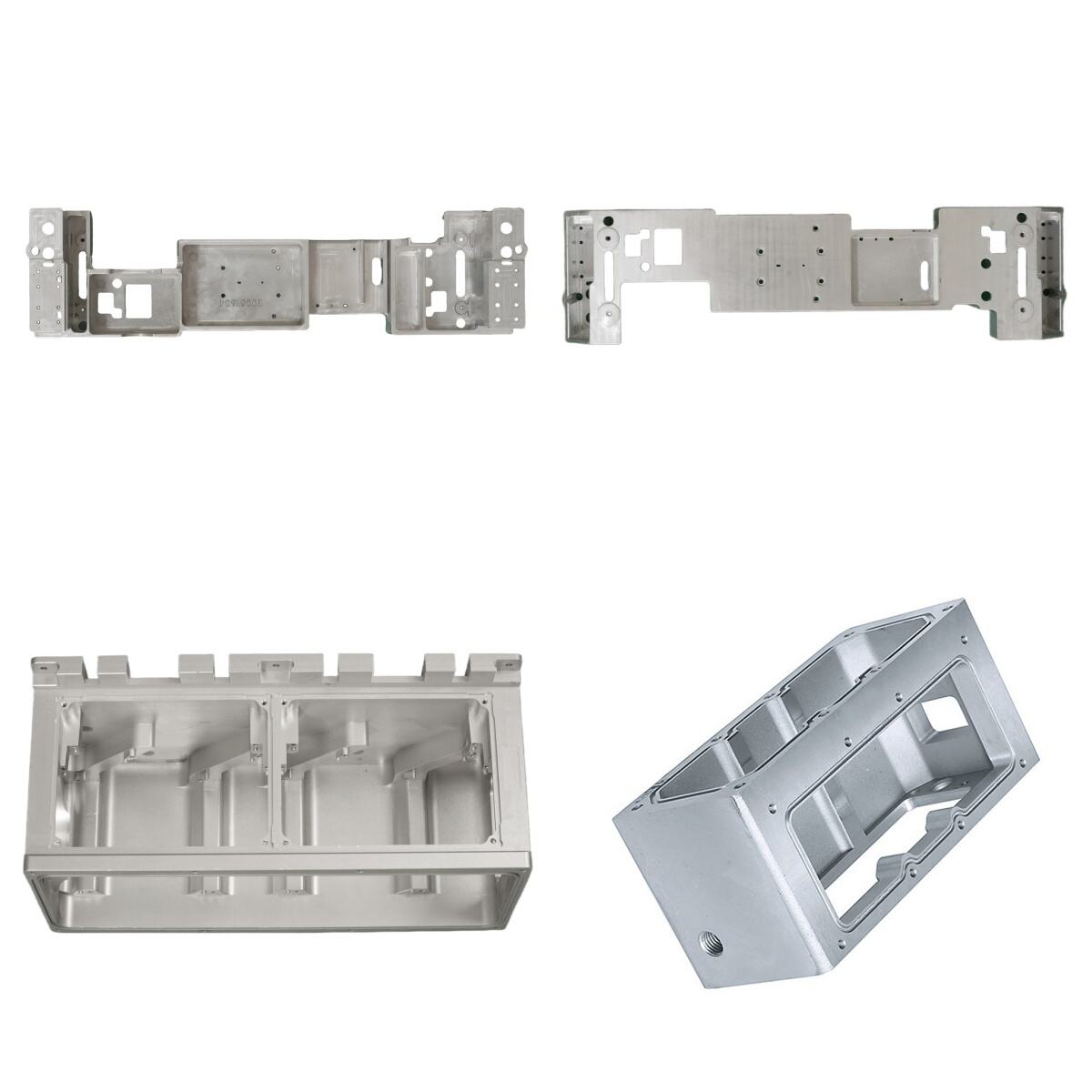

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is widely recognized for its ability to produce complex shapes with high dimensional accuracy and excellent surface finish. At Shenzhen Jingrui Precision Technology Co., Ltd., we employ state-of-the-art die casting methods that cater to a variety of industries, including aerospace, automotive, and construction.

Our production facilities span 10,000 square meters and are equipped with cutting-edge technology, enabling us to handle a diverse range of materials including stainless steel, aluminum, copper, and iron. Our team of over 140 skilled employees, including 35 technical experts and 7 senior engineers, ensures that we maintain high standards throughout the manufacturing process.

With an annual output value exceeding 80 million yuan, our commitment to quality and innovation has positioned us as a leader in the die casting industry. We prioritize customer satisfaction, offering tailored solutions that meet specific project requirements while adhering to international quality standards.

Our die casting services not only enhance the efficiency of production but also reduce waste, making it an environmentally friendly option. We utilize advanced testing and inspection techniques to ensure that every product we deliver meets or exceeds the required specifications for precision, strength, and durability. As a high-tech enterprise recognized for our innovation, we continuously invest in research and development to stay at the forefront of the die casting industry.

By choosing Shenzhen Jingrui Precision Technology Co., Ltd. as your partner for die casting solutions, you are guaranteed exceptional quality, competitive pricing, and unparalleled customer service. Let us help you bring your projects to life with our precision die casting services.