Casting aluminum is a crucial process in the manufacturing of high-quality metal components, particularly for industries that demand precision and reliability. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage our extensive experience and advanced technology to offer top-tier casting aluminum services. Our commitment to quality is reflected in our ISO 9001:2015 certification, which guarantees that every product we manufacture adheres to stringent quality standards.

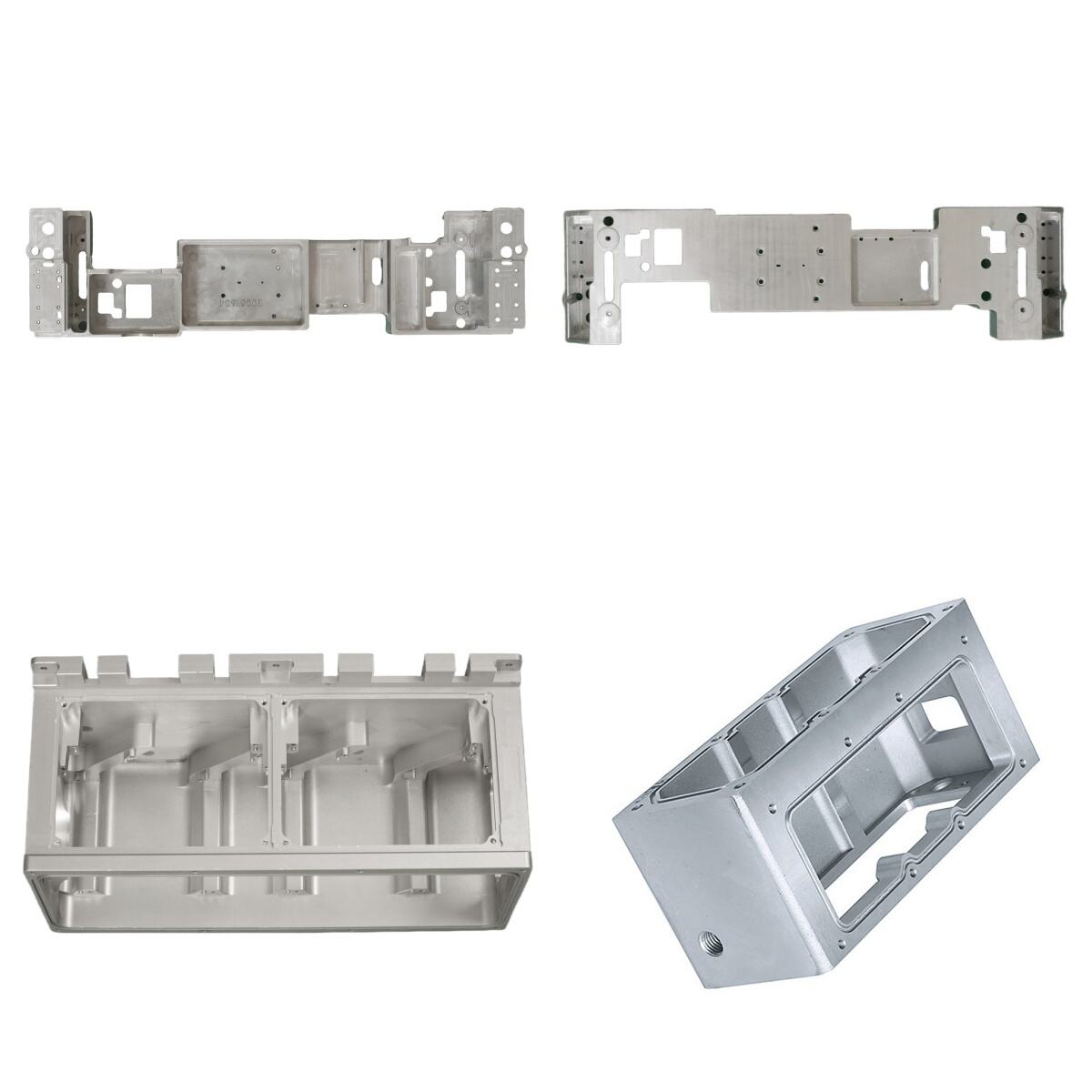

Our casting aluminum process begins with the careful selection of raw materials. We utilize high-grade aluminum alloys, ensuring that our products possess excellent mechanical properties and corrosion resistance. Our state-of-the-art facilities are equipped with precision casting and CNC machining capabilities, allowing us to produce complex geometries with exceptional accuracy.

We understand that different industries have unique requirements. Therefore, we offer customized casting aluminum solutions tailored to meet specific application needs. Whether you are in the aerospace sector requiring lightweight components or in automotive manufacturing needing durable parts, our team is equipped to deliver high-quality solutions.

Quality assurance is at the core of our operations. We employ advanced testing equipment, including component analyzers and flaw detectors, to ensure that every casting aluminum product meets or exceeds client expectations. Our experienced engineers conduct thorough inspections throughout the manufacturing process, from raw material procurement to final product delivery.

In addition to our manufacturing capabilities, we pride ourselves on our customer-centric approach. We work closely with our clients to understand their needs and provide personalized support throughout the project lifecycle. Our goal is to not only meet but exceed your expectations, delivering products that enhance your operational efficiency and success.