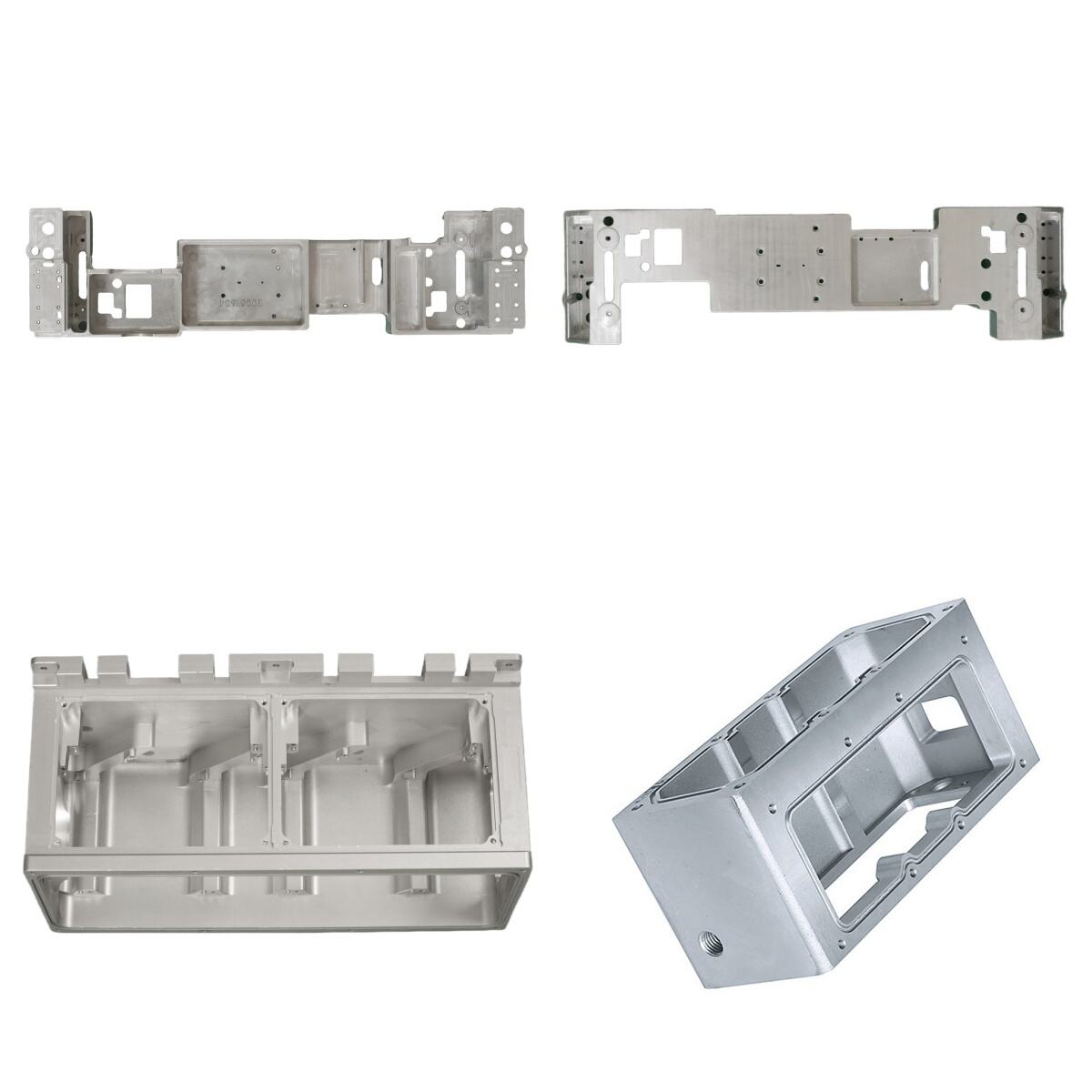

High pressure die casting is a highly efficient manufacturing method used for producing complex metal parts with superior surface quality and dimensional accuracy. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage this technique to create components from a variety of materials, including aluminum alloys, zinc alloys, and magnesium alloys.

The process begins with molten metal being injected into a mold under high pressure, which allows for the rapid cooling and solidification of the metal. This method not only reduces production times but also minimizes waste, making it an environmentally friendly option for metal manufacturing. Our high pressure die casting services are ideal for industries such as automotive manufacturing, where precision and reliability are paramount.

We pride ourselves on our ability to customize die casting solutions based on the unique specifications of our clients. Our experienced engineers work closely with customers to design molds that optimize the casting process and ensure that the final products meet stringent performance criteria. Each stage of production, from material selection to final inspection, is meticulously monitored to guarantee the highest quality standards.

In addition to our commitment to quality, we also focus on innovation. Our continuous investment in advanced technology and equipment enables us to stay at the forefront of the industry, providing our clients with cutting-edge solutions that enhance their competitive edge. Whether you are looking for high volume production or specialized components, Shenzhen Jingrui Precision Technology Co., Ltd. is your trusted partner for high pressure die casting.