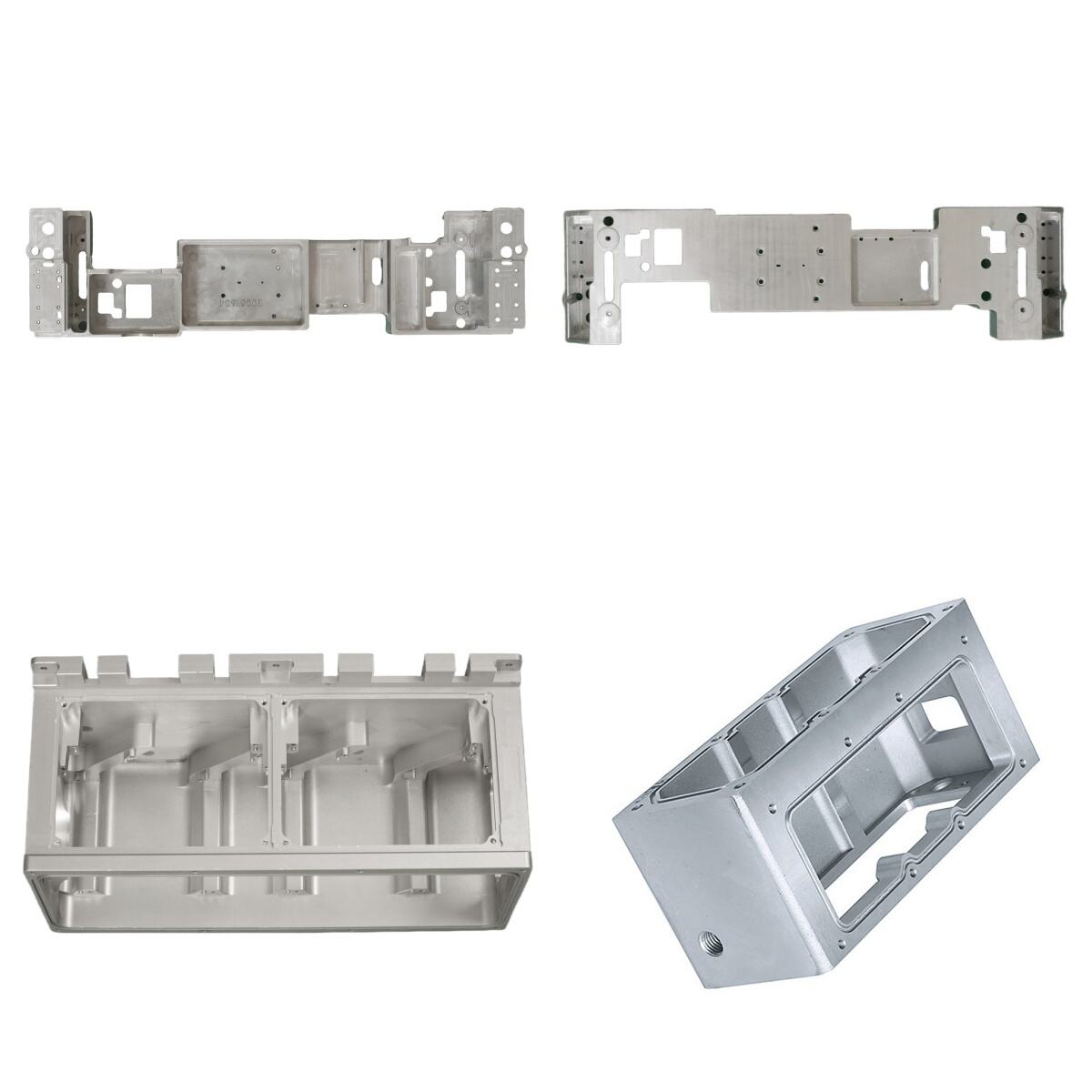

Permanent die casting is a manufacturing process that produces metal parts with high precision and excellent surface finish. This technique is particularly beneficial for producing complex shapes and intricate designs, making it ideal for industries such as automotive, aerospace, and electronics. At Shenzhen Jingrui Precision Technology Co., Ltd., we utilize advanced die casting technologies to create parts from various materials, including aluminum alloys and zinc.

The process begins with the design of the die, which is a crucial step that determines the final product’s shape and features. Our engineers work closely with clients to develop die designs that optimize production efficiency and minimize waste. Once the die is created, molten metal is injected into it under high pressure, allowing for rapid cooling and solidification. This results in components with excellent dimensional accuracy and surface quality.

Our commitment to quality is unwavering. We adhere to the ISO 9001:2015 Quality Management System, ensuring that every step of production, from material selection to final inspection, meets the highest standards. Our advanced testing equipment, including component analyzers and CMMs, allows us to verify the integrity and performance of each part before it reaches our clients.

In addition to our production capabilities, we pride ourselves on our customer-centric approach. We understand the importance of timely delivery and responsive communication, which is why we work diligently to meet our clients’ schedules and expectations. Our goal is to provide not just products, but solutions that empower businesses to succeed in their respective markets.