Gravity casting, a widely recognized method in the metal manufacturing industry, involves pouring molten metal into a mold under the influence of gravity. This technique is particularly advantageous for producing complex geometries and achieving a high level of detail in finished products. At Shenzhen Jingrui Precision Technology Co., Ltd., we specialize in gravity casting, utilizing advanced technologies and skilled expertise to deliver superior metal components that cater to a diverse array of industries.

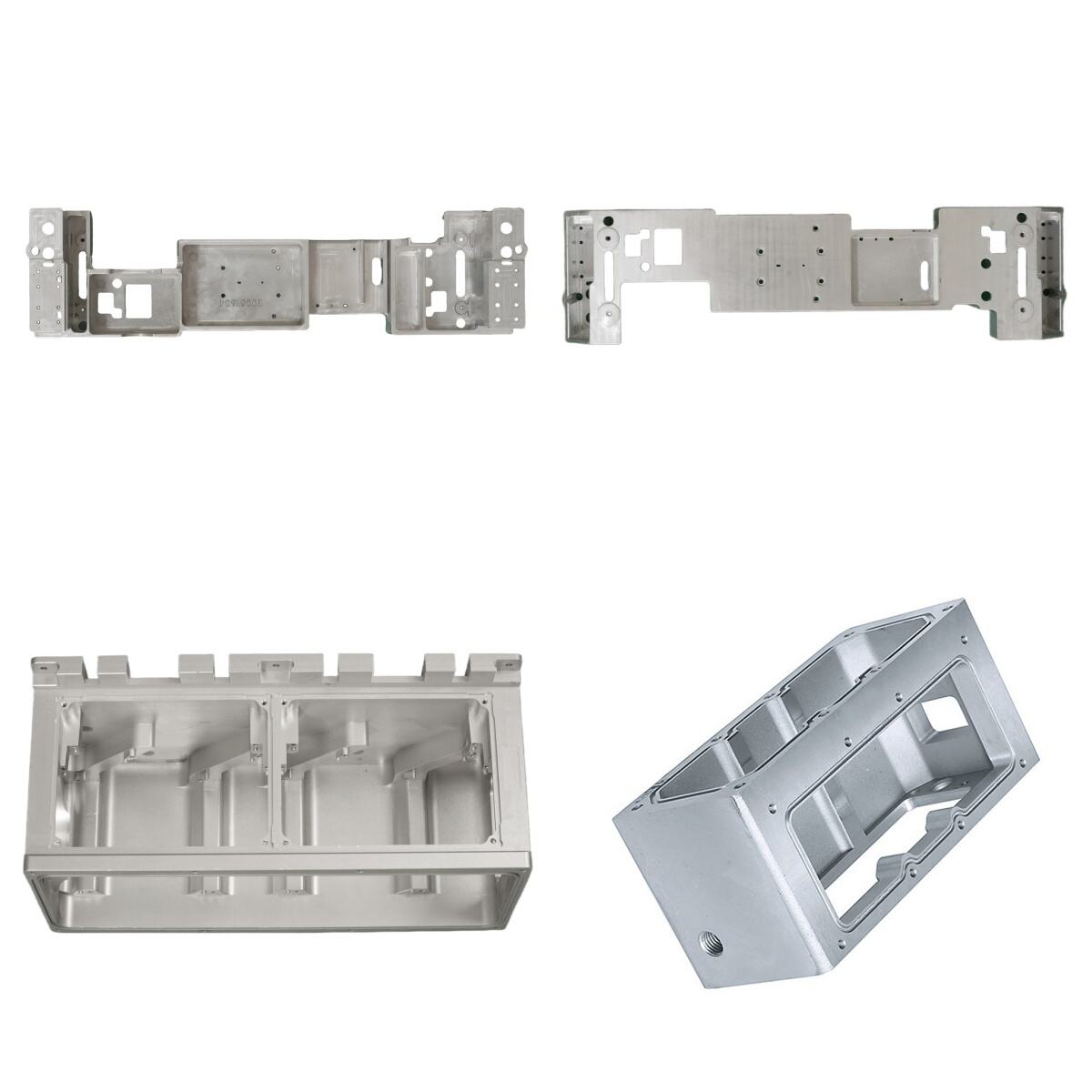

Our gravity casting process begins with the careful selection of raw materials, including various grades of aluminum alloys, copper, and iron. This selection is crucial as it directly impacts the mechanical properties and durability of the final product. Once the materials are sourced, they are melted and poured into precision-engineered molds, where gravity ensures that the molten metal fills every nook and cranny of the mold, creating intricate designs with minimal defects.

After casting, each component undergoes a series of rigorous inspections and testing procedures to ensure compliance with international quality standards. Our investment in cutting-edge testing equipment, such as coordinate measuring machines (CMM) and tensile testing machines, allows us to assess the precision and structural integrity of our gravity cast components thoroughly.

The versatility of gravity casting makes it suitable for a wide range of applications, including but not limited to aerospace components, automotive parts, and construction machinery. With a focus on custom solutions, we collaborate closely with our clients to understand their specific needs and deliver products that enhance their operational efficiency. Our commitment to innovation and excellence positions us as a leader in the gravity casting sector, ready to meet the evolving demands of the global market.