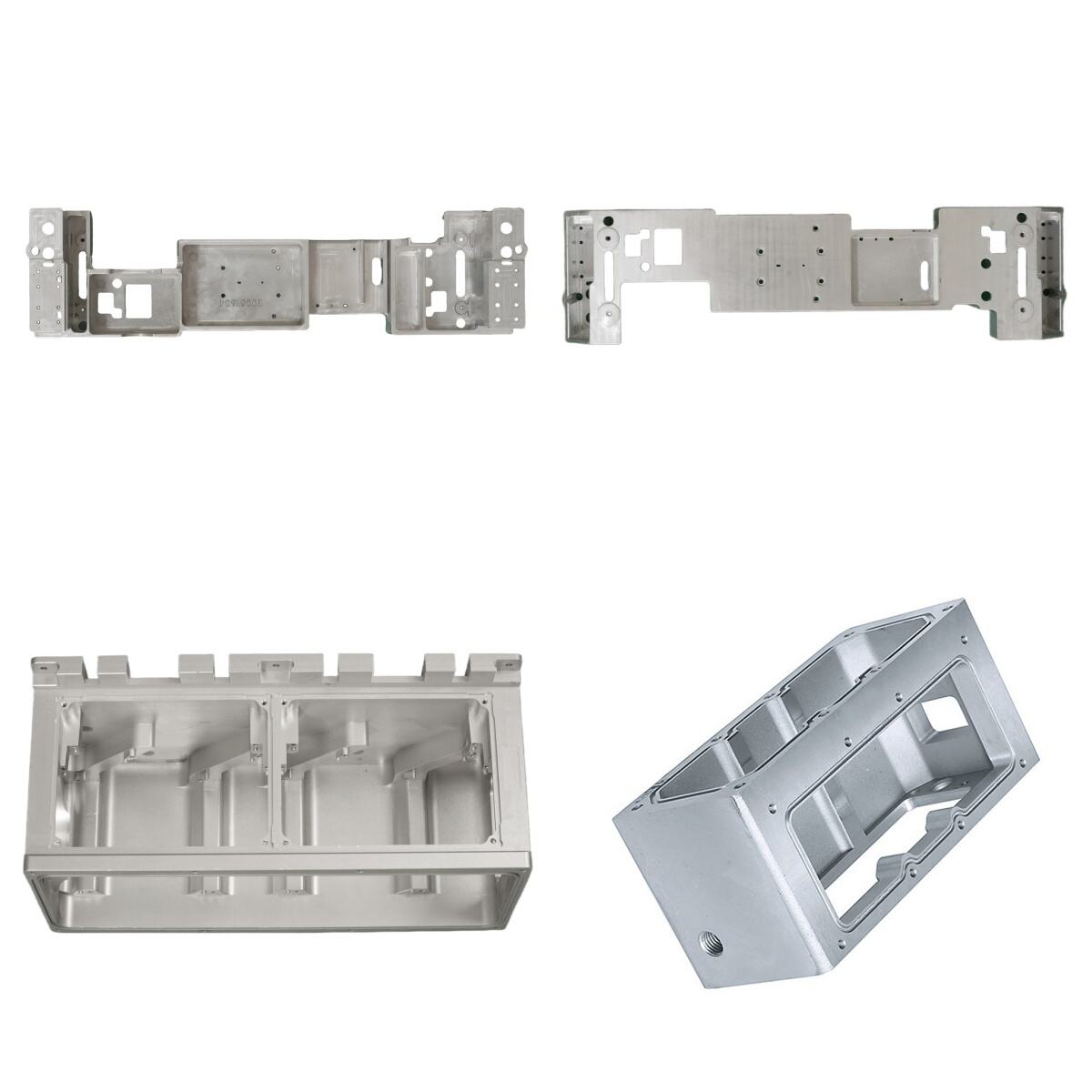

Gravity die casting is a highly efficient process used to manufacture complex metal components with exceptional precision and surface finish. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage advanced gravity die casting techniques to produce high-quality parts for various applications. Our process involves pouring molten metal into a reusable steel mold, which allows for greater dimensional accuracy and a superior surface finish compared to traditional sand casting methods.

The versatility of gravity die casting makes it suitable for a wide range of materials, including aluminum, copper, and various alloys. This process is particularly beneficial for producing components in industries such as aerospace, automotive, and construction machinery, where precision and reliability are paramount. Our skilled engineers work closely with clients to develop customized solutions that meet specific performance and design requirements.

Our gravity die casting services are complemented by our extensive capabilities in CNC machining, allowing us to further refine and finish components to exact specifications. We utilize advanced inspection techniques to ensure that each part meets stringent quality standards, providing our customers with peace of mind regarding the performance and longevity of their products.