Zinc alloy die casting is a highly efficient manufacturing process that allows for the production of complex shapes with exceptional dimensional accuracy. At Shenzhen Jingrui Precision Technology Co., Ltd., we specialize in this process, utilizing our state-of-the-art facilities to produce high-quality zinc alloy components. Zinc alloys, known for their excellent fluidity, corrosion resistance, and strength, are ideal for various applications across multiple industries.

Our die casting process begins with the careful selection of high-quality raw materials, ensuring that the final products meet stringent performance standards. We employ advanced die casting techniques, including high-pressure die casting, which enables us to create intricate designs with smooth surfaces and tight tolerances. Our skilled engineers and technicians oversee every stage of production, from mold design to final inspection, guaranteeing that each component meets the exact specifications of our clients.

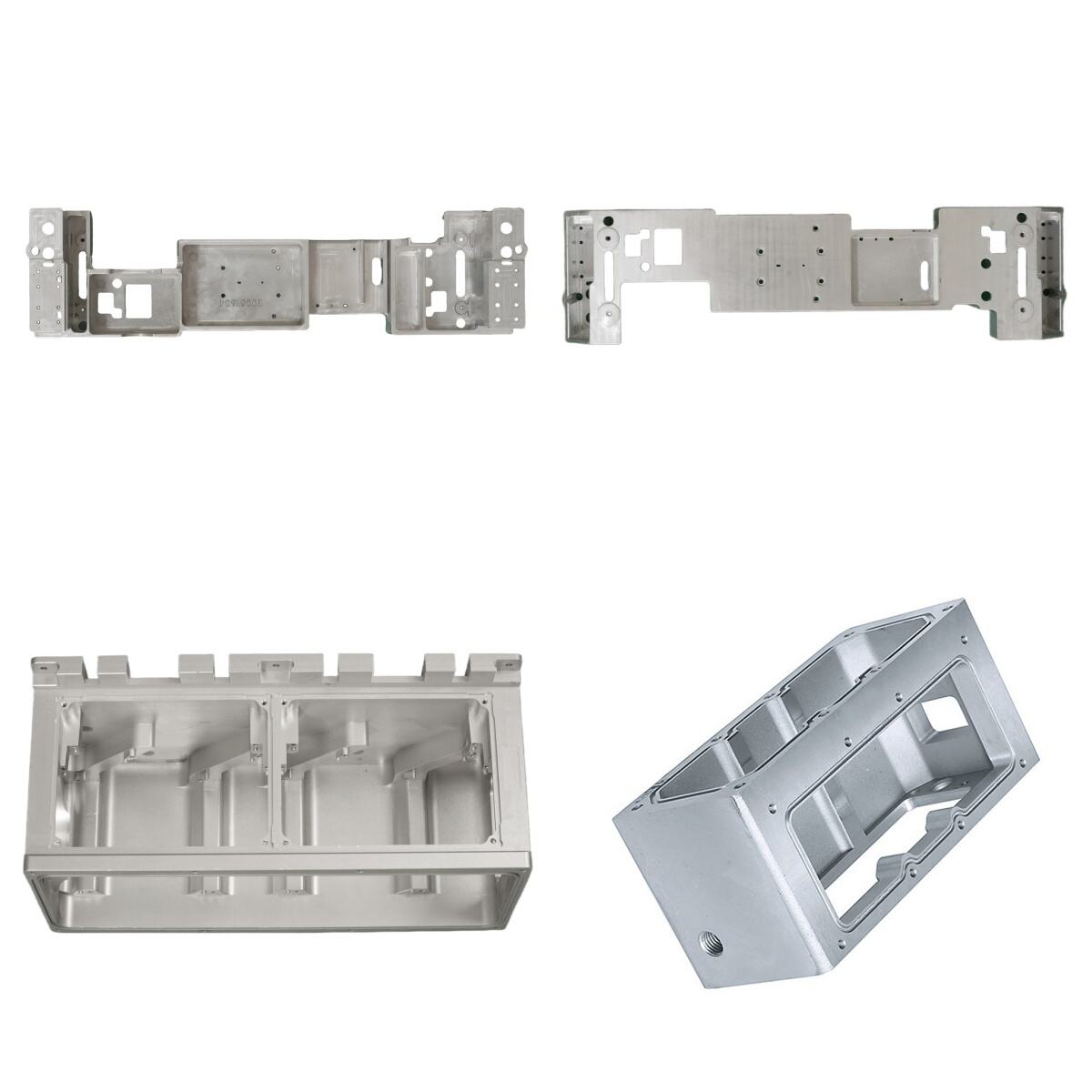

In addition to our commitment to quality, we offer tailored solutions to meet the diverse needs of our clients. Our zinc alloy die casting products are widely used in industries such as automotive manufacturing, aerospace, electronics, and hardware tools. We understand that different applications require different properties, and our team is dedicated to providing customized solutions that enhance performance and durability.

With a focus on innovation and customer satisfaction, we continuously invest in research and development to improve our die casting processes and explore new applications for zinc alloys. Our goal is to be your premier partner in precision metal manufacturing, delivering not only products but also value-added services that help you succeed in your business.