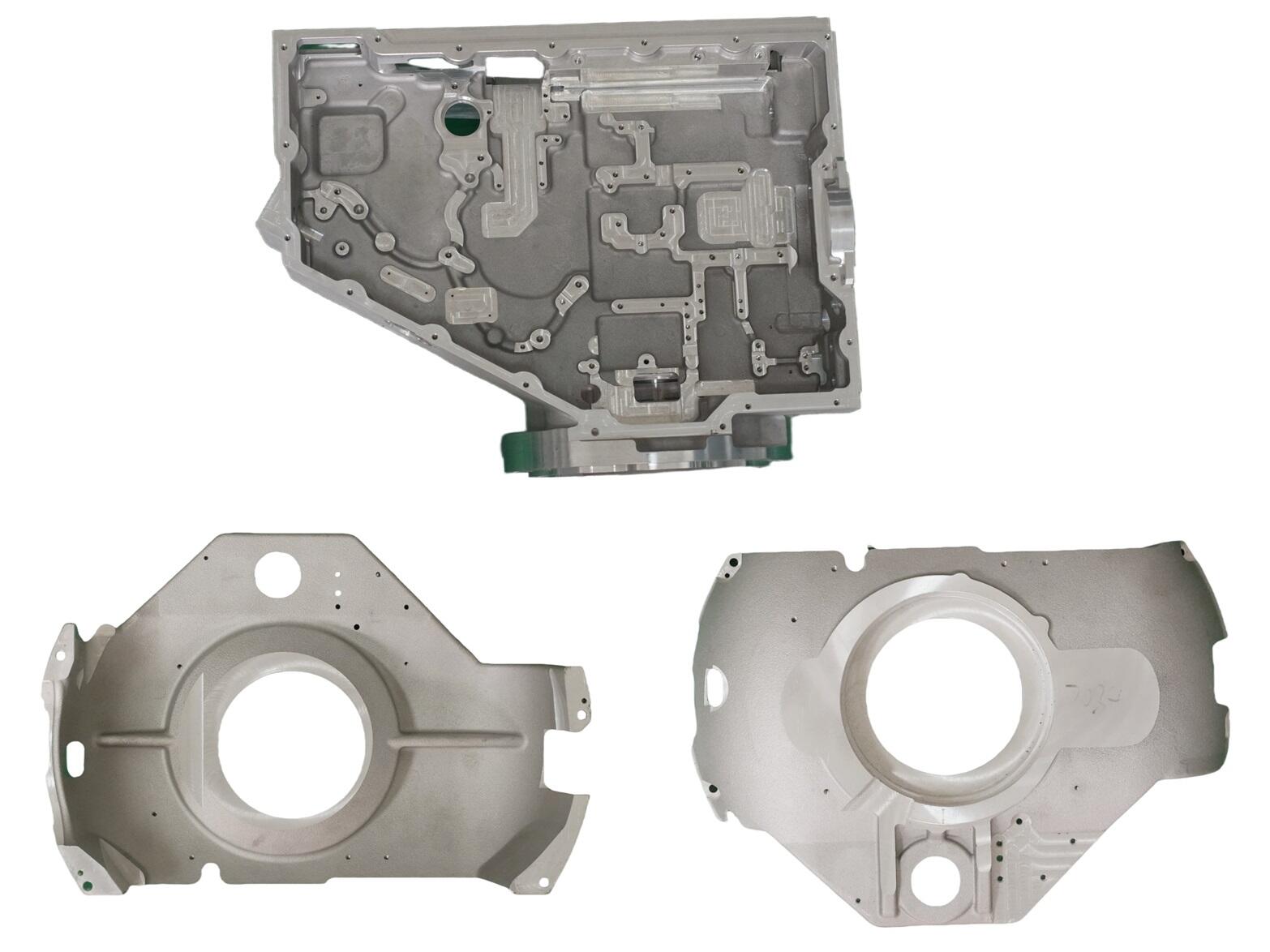

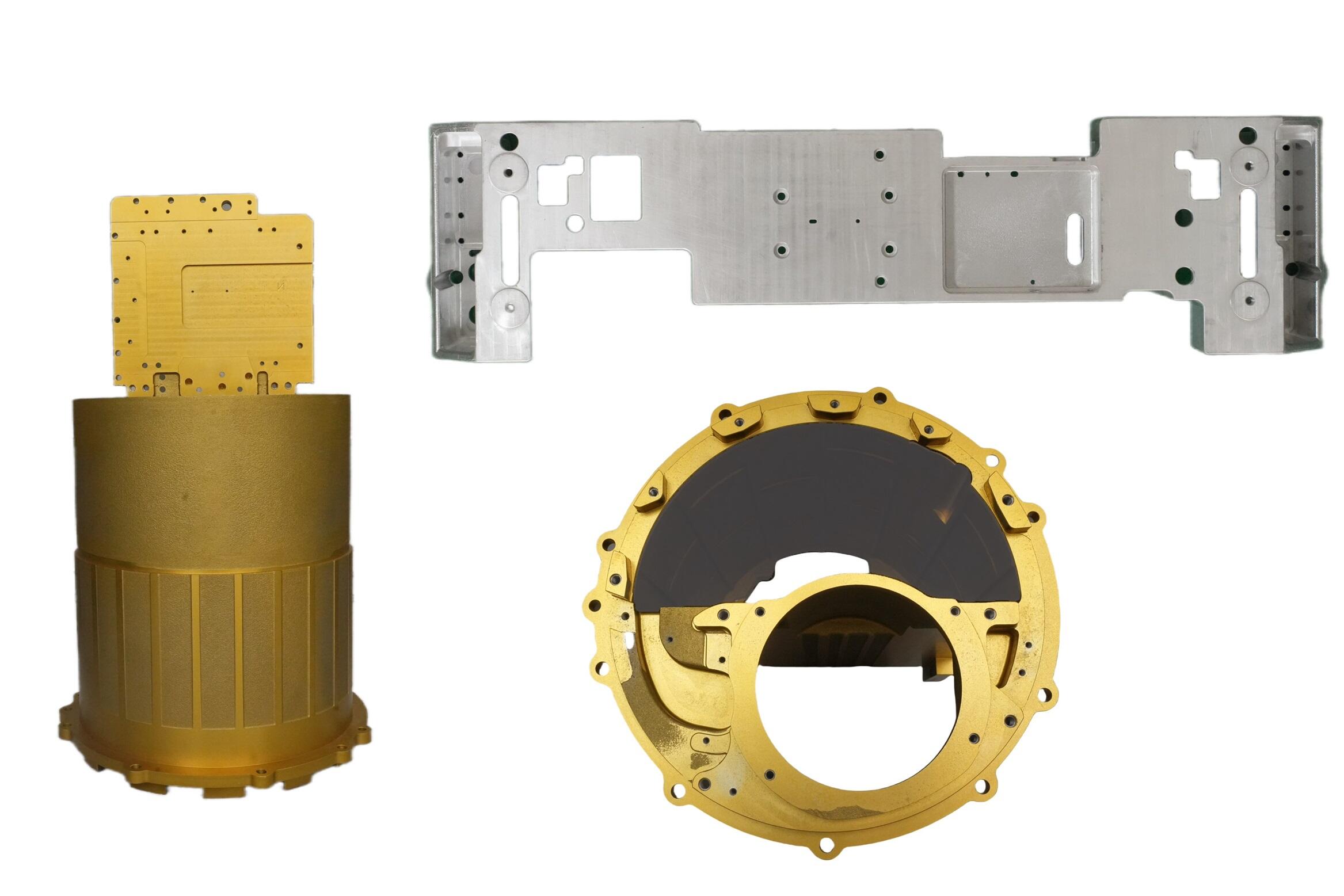

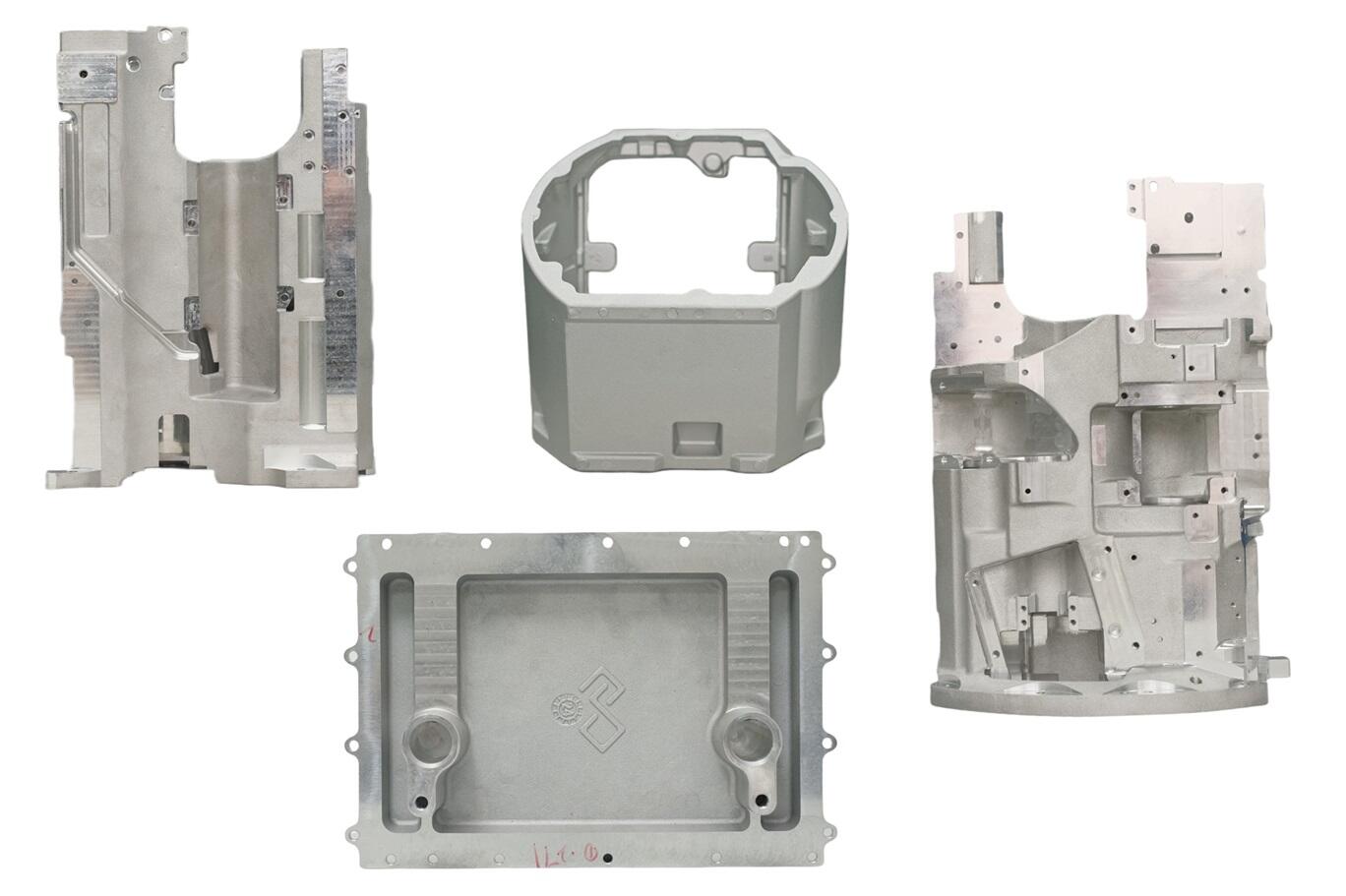

Gravity casting aluminium is a highly efficient manufacturing process that utilizes the force of gravity to fill a mold with molten aluminium. This method is particularly advantageous for producing intricate shapes with excellent surface finishes and dimensional accuracy. At Shenzhen Jingrui Precision Technology Co., Ltd., we have invested in cutting-edge gravity casting technology, enabling us to produce high-quality aluminium components that meet the diverse needs of our clients.

The gravity casting process begins with creating a mold, typically made from metal, which can withstand high temperatures. Once the mold is prepared, molten aluminium is poured into it, relying on gravity to ensure complete filling. This method minimizes air pockets and defects, resulting in a superior end product. The cooling process is carefully controlled to prevent warping and ensure uniform material properties across the casting.

Our factory, spanning 10,000 square meters, is equipped with advanced production workshops dedicated to gravity casting aluminium. With over 140 skilled employees, including 35 technical experts and 7 senior engineers, we maintain a robust production capacity that exceeds 80 million yuan annually. This capability ensures that we can handle large orders while maintaining the highest quality standards.

We cater to various industries, including aerospace, automotive, and construction machinery. Our gravity cast aluminium products are used in critical applications where reliability and performance are paramount. By leveraging our expertise and state-of-the-art facilities, we provide solutions that enhance your product offerings and operational efficiencies.