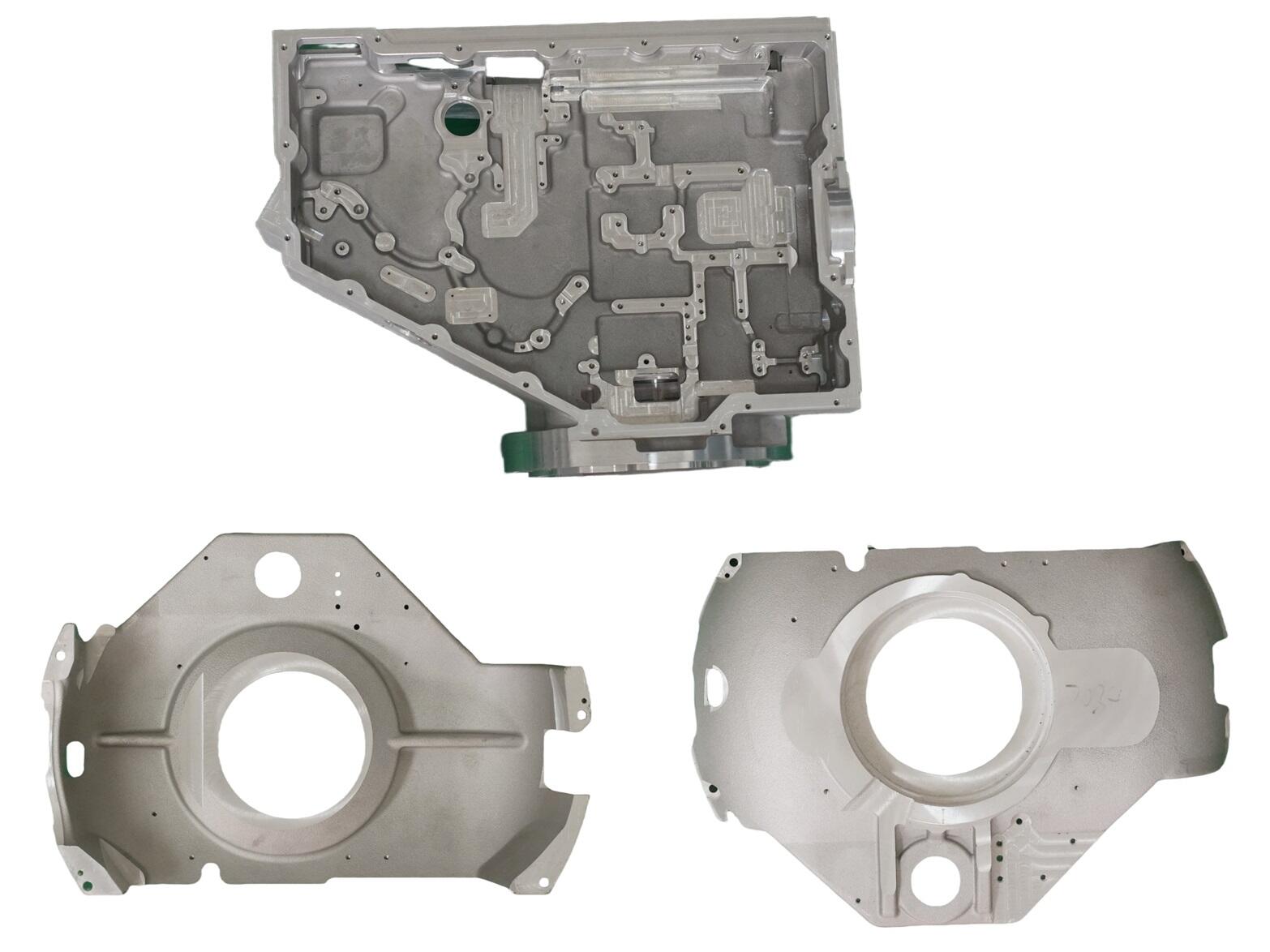

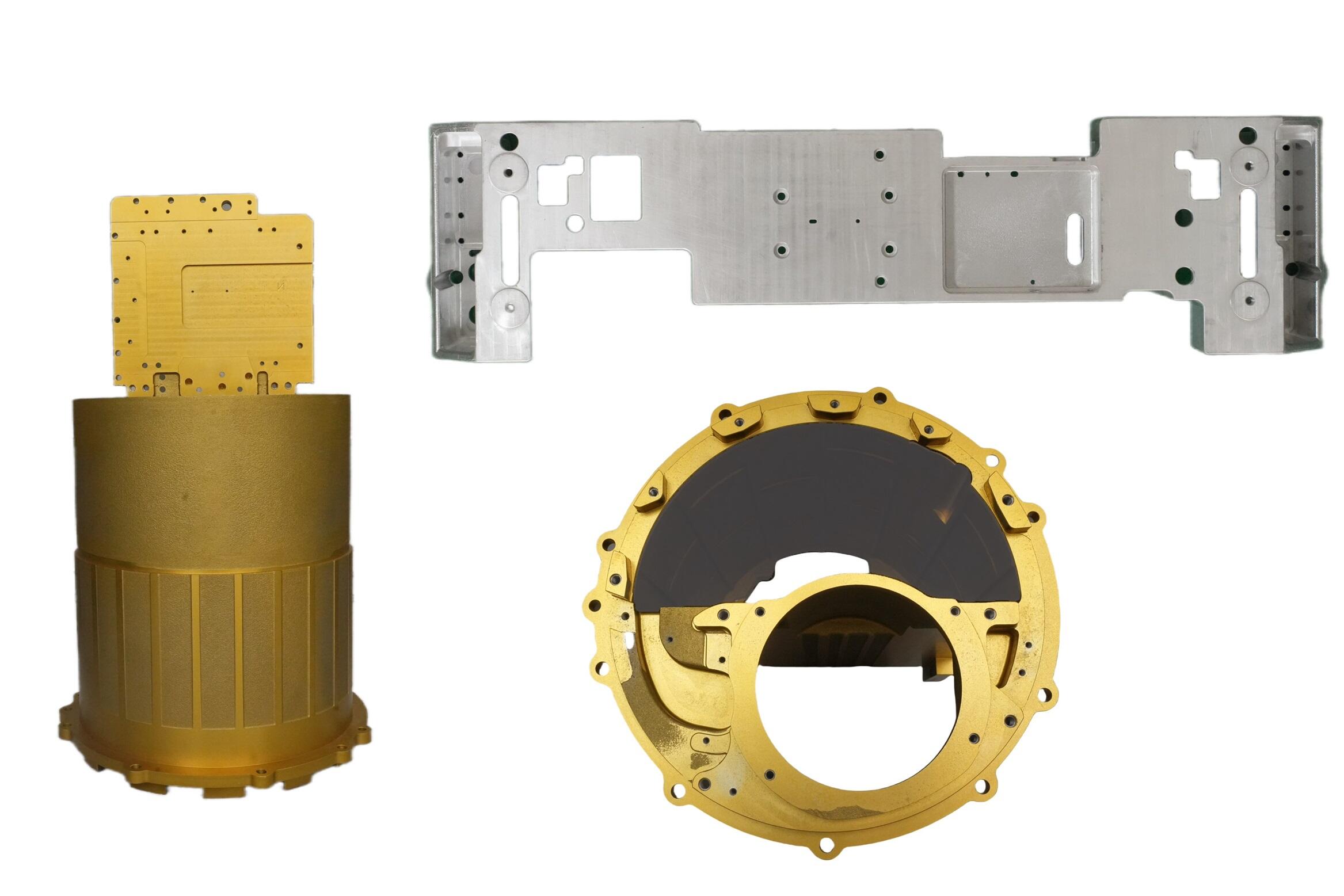

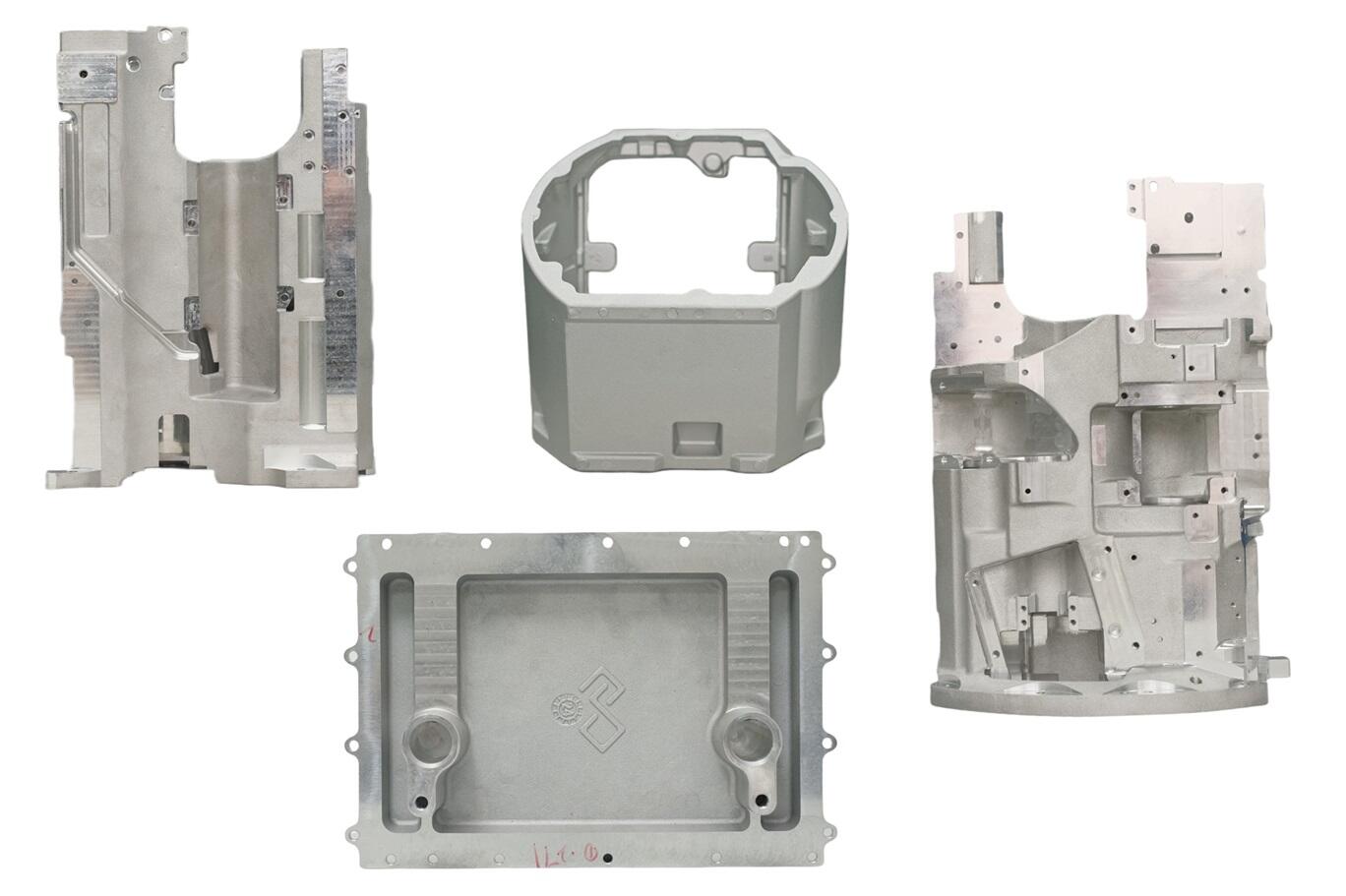

Aluminum gravity casting is a highly efficient method for producing intricate and high-strength components across various industries. This process involves pouring molten aluminum into a mold, relying on gravity to fill the mold cavity, which results in superior dimensional accuracy and surface finish compared to other casting methods. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage advanced machinery and techniques to ensure that our aluminum gravity casting products meet the specific needs of our clients.

Our facility is equipped with cutting-edge CNC machining centers, enabling us to perform secondary operations that enhance the functionality and aesthetics of the cast parts. We cater to a wide range of applications, from lightweight automotive components to robust machinery parts, ensuring that our clients receive products that are both reliable and efficient.

In addition to our technical expertise, we prioritize customer satisfaction by providing comprehensive support throughout the production process. From initial design consultations to final inspections, our dedicated team works closely with clients to ensure that every aspect of their project is handled with care and precision. This customer-centric approach, combined with our commitment to quality and innovation, positions us as a leader in the aluminum gravity casting industry.