Shenzhen Jingrui Precision Technology Co., Ltd. is your premier partner for gravity die casting manufacturing. Established in 2006, we have built a reputation as a high-tech enterprise dedicated to producing precision metal parts. Our gravity die casting process is known for its ability to create complex shapes with exceptional surface finishes and dimensional accuracy.

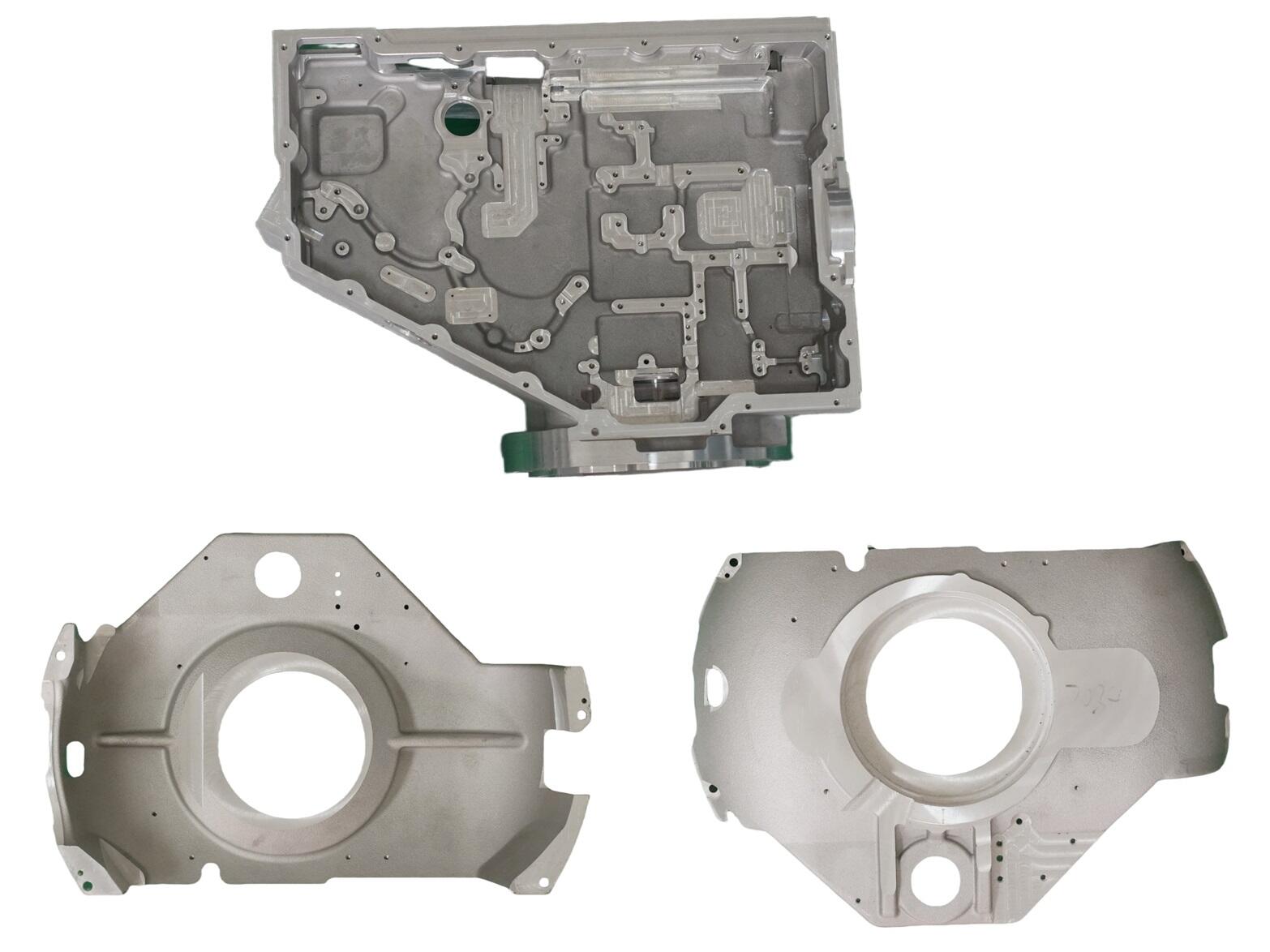

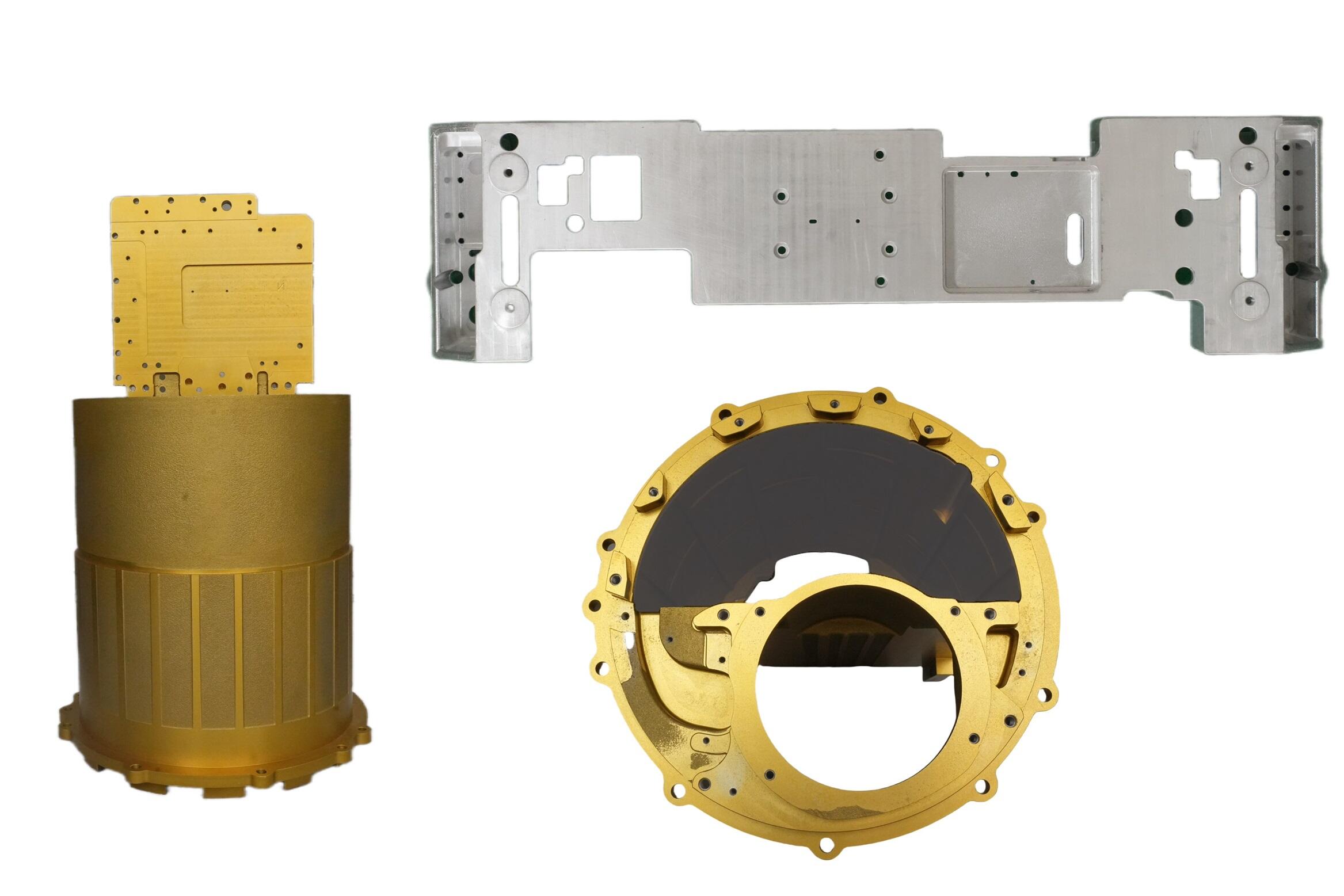

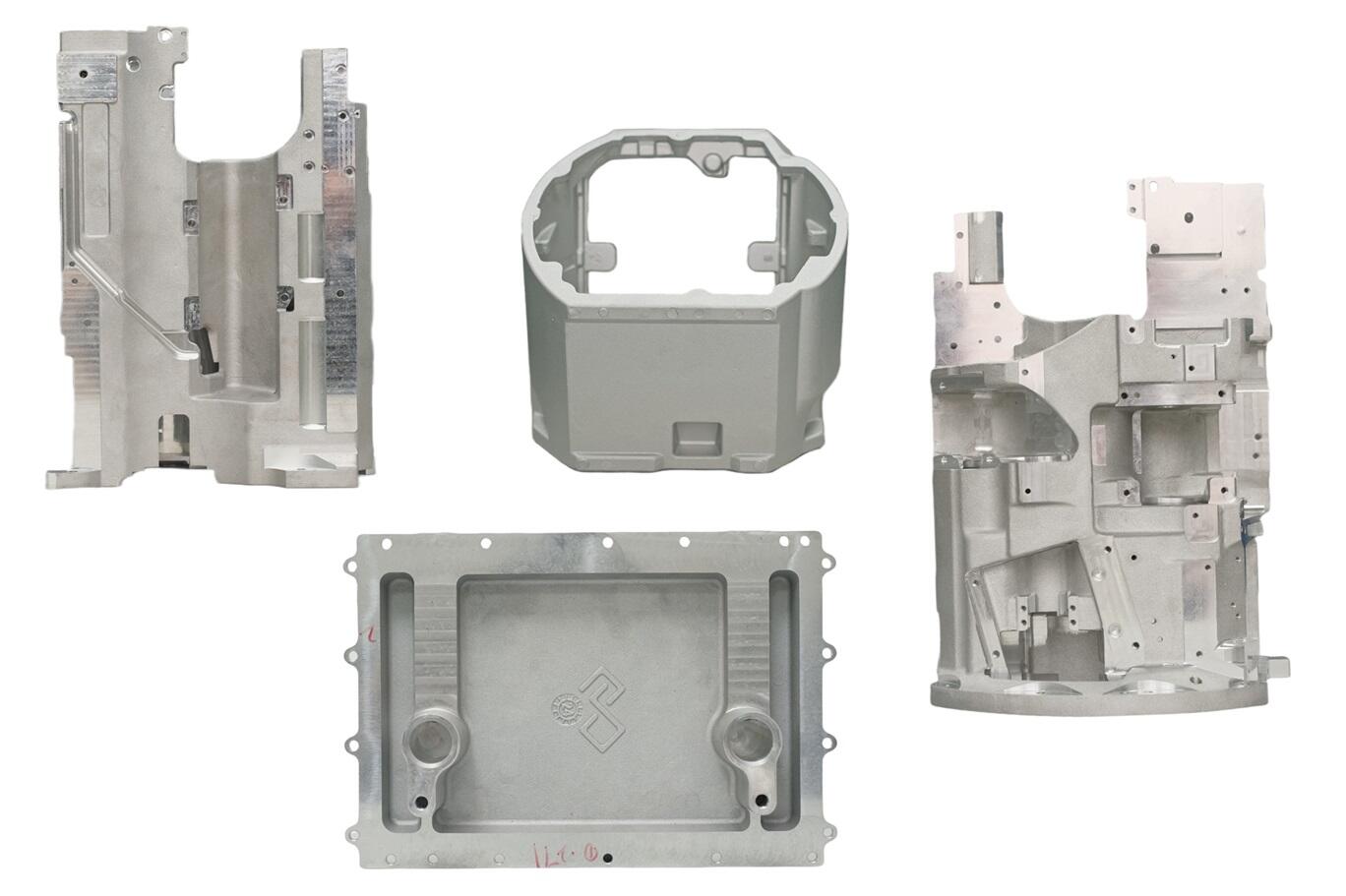

We utilize advanced techniques and high-quality materials, including aluminum and zinc alloys, to produce components that meet rigorous industry standards. Our skilled workforce, comprising over 140 employees, including 35 technical experts, ensures that every product is crafted with precision and care.

Our manufacturing capabilities extend beyond gravity die casting; we also provide CNC machining, mechanical parts finishing, and heat treatment services. Each stage of production is meticulously monitored to adhere to our ISO 9001:2015 certification, guaranteeing that our clients receive only the best products.

We serve a wide array of industries, from automotive and aerospace to construction and hardware tools, ensuring that our solutions are both versatile and tailored to meet the specific needs of our clients. With an annual output value exceeding 80 million yuan, we are well-equipped to handle large scale orders while maintaining the highest quality standards.

At Shenzhen Jingrui, we pride ourselves on our ability to deliver customized solutions that not only meet but exceed customer expectations. Our commitment to innovation and quality makes us the ideal choice for businesses seeking reliable gravity die casting manufacturers.