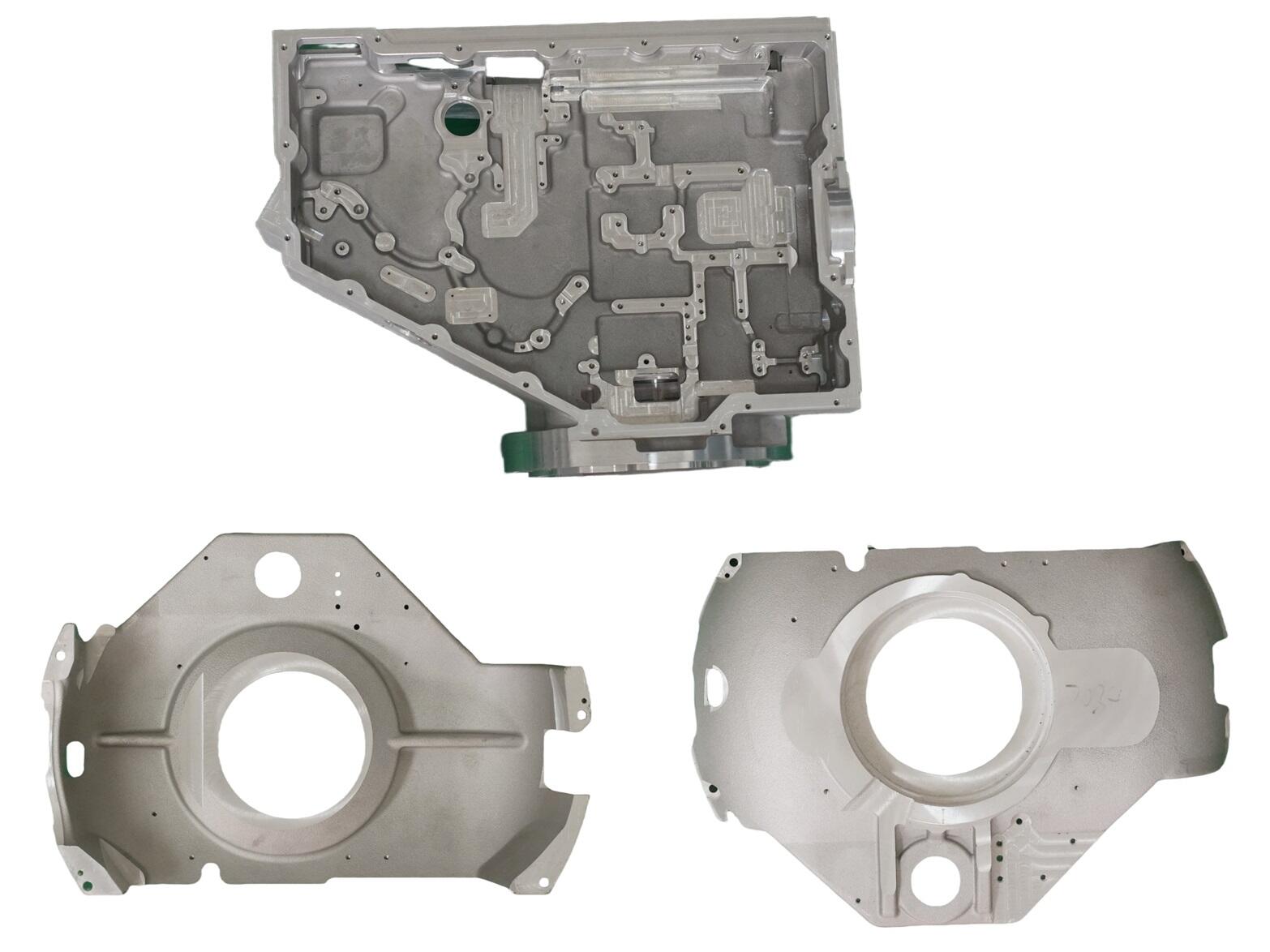

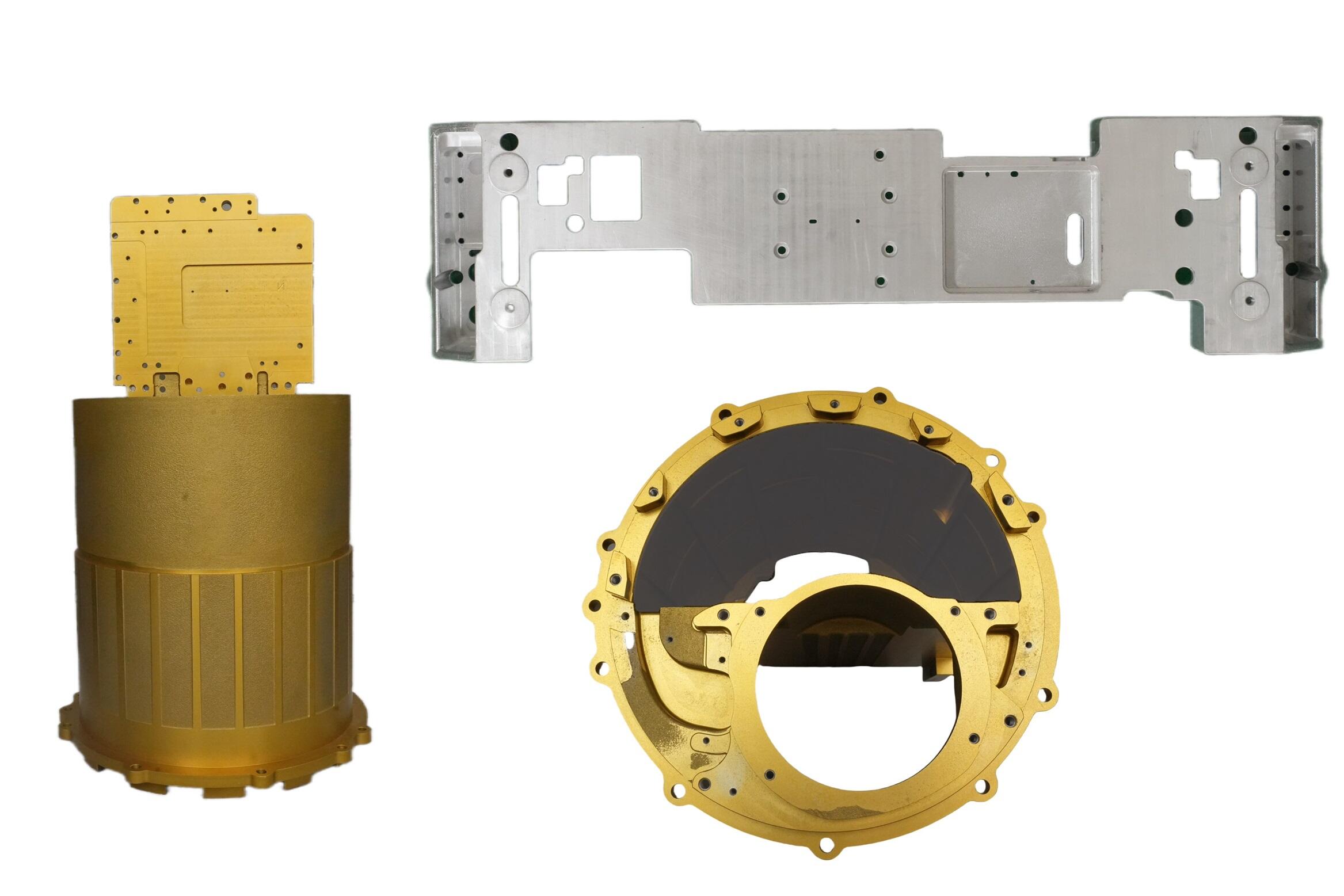

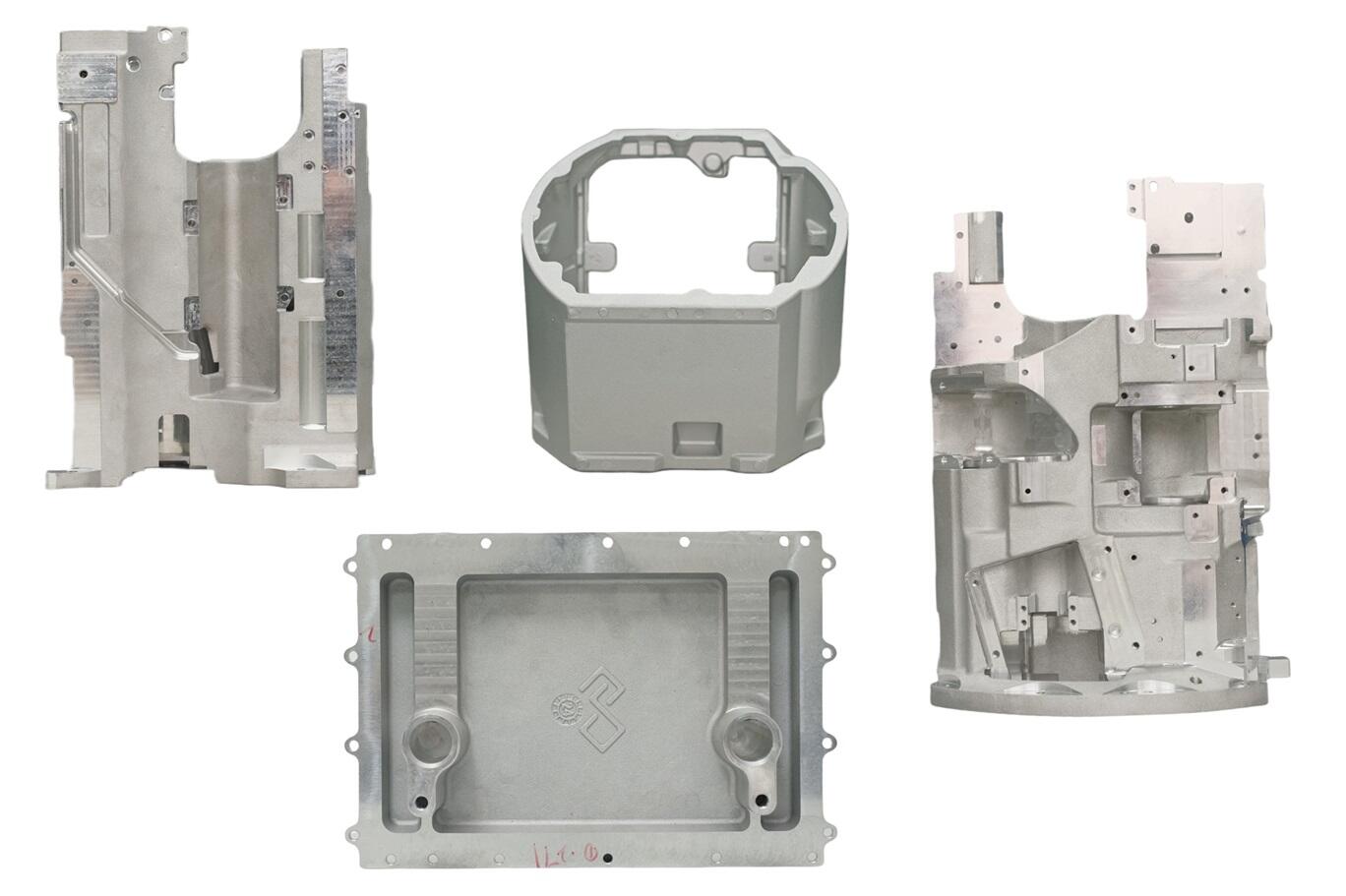

Aluminium gravity die casting is a highly efficient manufacturing process that produces complex shapes with excellent dimensional accuracy and surface finish. This method involves pouring molten aluminium into a reusable steel die, allowing for high-volume production of intricate components. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage this technique to create high-quality parts that cater to various industries, including aerospace, automotive, and construction machinery.

Our commitment to precision and quality is evident in our state-of-the-art facilities, which are equipped with advanced CNC machining centers and rigorous quality assurance processes. We adhere to the ISO 9001:2015 Quality Management System, ensuring that our products consistently meet or exceed customer expectations.

The advantages of aluminium gravity die casting include:

High Strength-to-Weight Ratio:Aluminium components are lightweight yet strong, making them ideal for applications where weight savings are critical.

Excellent Surface Finish:The gravity die casting process results in smooth surfaces that often require minimal finishing, reducing overall production time and costs.

Cost-Effectiveness:When produced in large quantities, aluminium gravity die casting offers significant cost savings compared to other manufacturing methods.

Our dedicated team of engineers and technicians works closely with clients to develop customized solutions that address specific challenges and requirements. Whether you need parts for automotive engines, aerospace components, or industrial machinery, we are here to provide the expertise and support you need to succeed.