Industrial Machined Parts Casting Services Stainless Steel Aluminum Hardware Sheet Metal Stampings

-Place of Origin: Guangdong, China

-Brand Name: jingrui

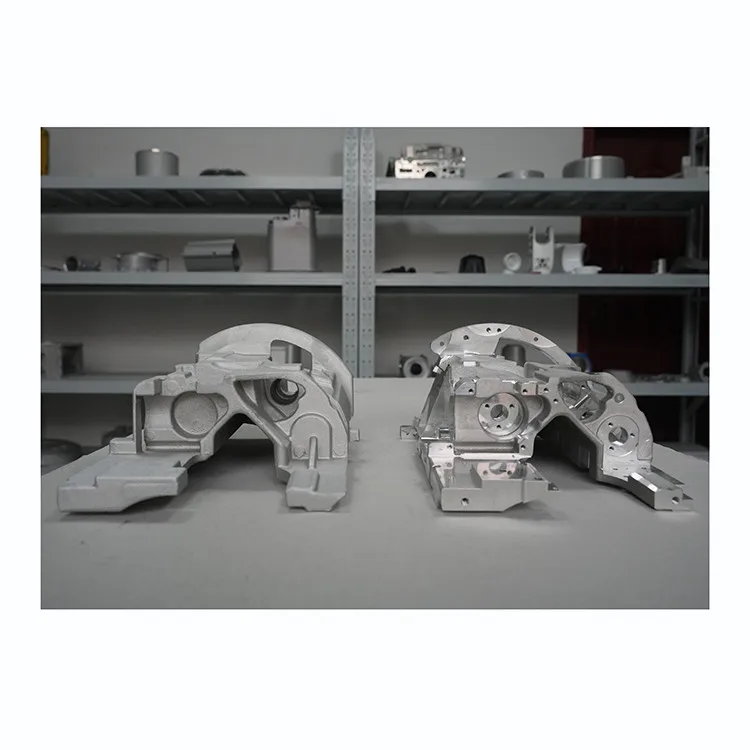

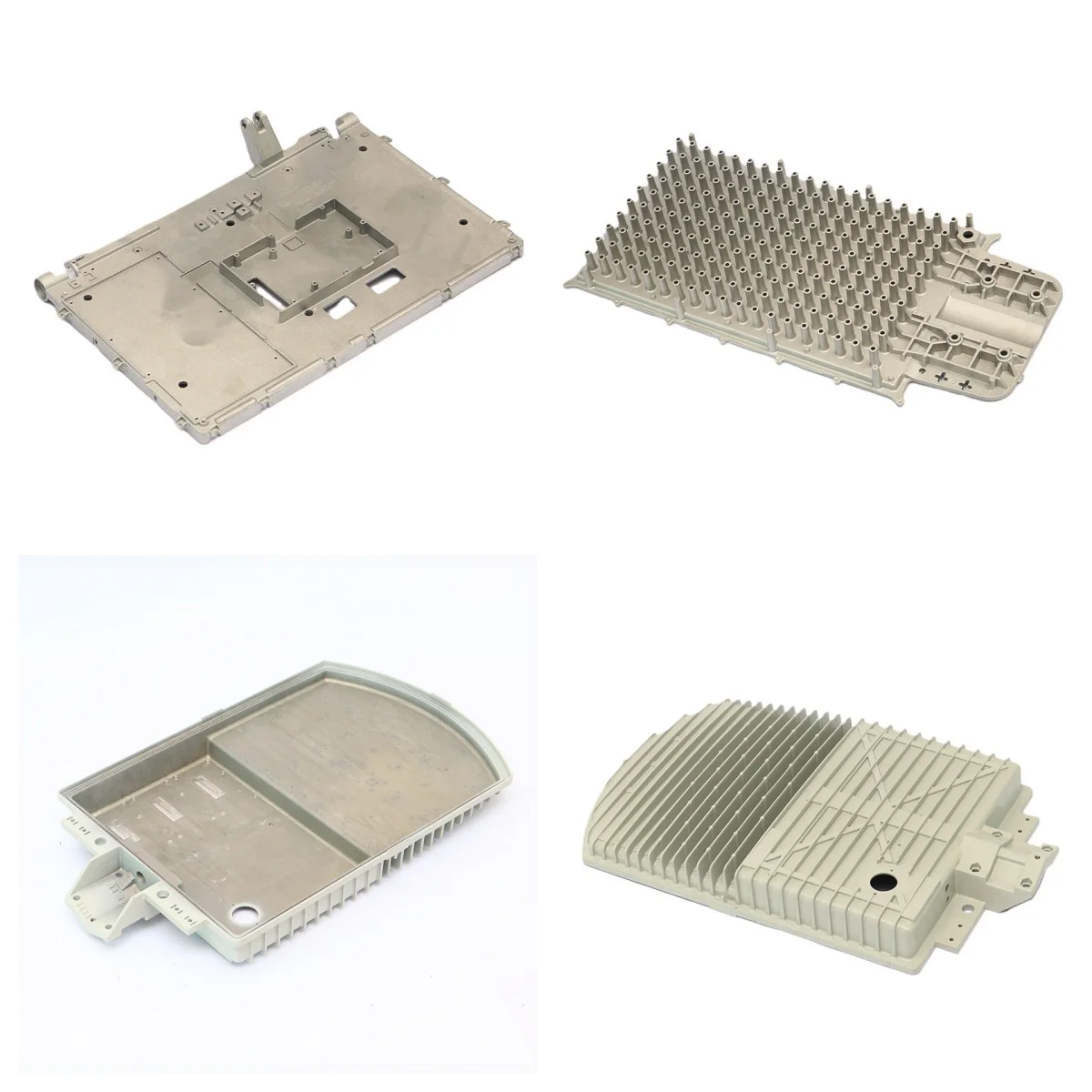

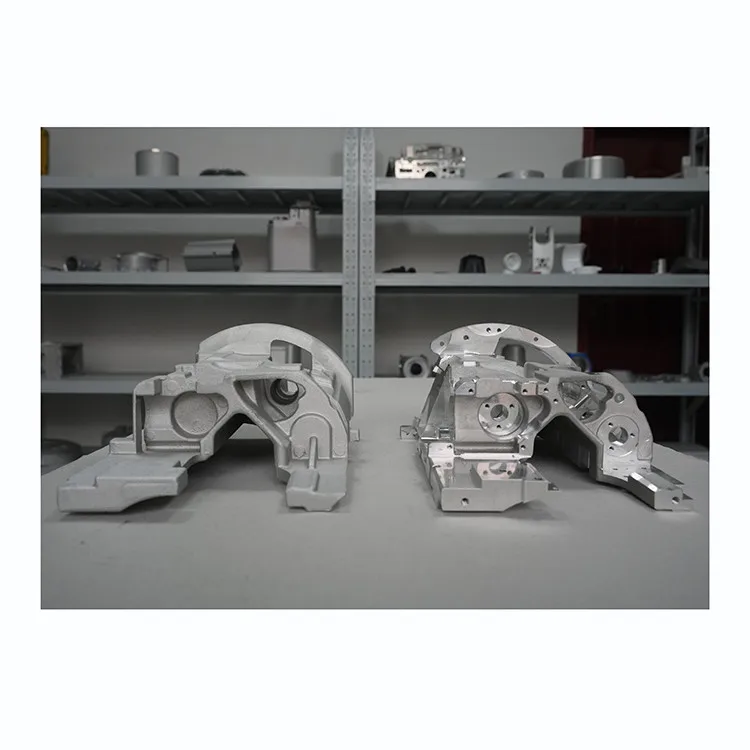

-Model Number: Gravity Casting

-Materials: Aluminium alloy or other

-Surface : Customer's requirement

- Overview

- Recommended Products

Place of Origin |

Guangdong, China |

Brand Name |

jingrui |

Model Number |

Gravity Casting |

Materials |

Aluminium alloy or other |

Service |

OEM/ODM |

Certification |

ISO 9001:2015 |

Standard |

Client Specification |

Color |

Customized Color |

Surface |

Customer's requirement |

Size |

Customer's requirement |

Quality Control |

Own testing center |

Package |

Bubble + Carton + Wooden Case |

Surface |

Customer's requirement |

Tolerance |

Customer's Drawing Request |

Shenzhen Jingrui Precision Technology Co., Ltd. - Your Premier Partner for Precision Metal Manufacturing Renowned as a High - tech Enterprise, Shenzhen Jingrui Precision Technology Co., Ltd. demonstrates un - wavering commitment to quality and innovation, holding the ISO 9001:2015 Quality Management System Certification. Since its establishment in 2006, our company has solidified its position as a leader in the hard - ware casting and CNC machining industry. Our factory occupies 10,000 square meters, with a workforce of over 140 dedicated employees. Among them, 35 are technical experts and 7 are senior engineers. Thanks to their proficie ncy we achieve an annual output value of more than 80 million yuan. State - of - the - Art Production Facilities We are equipped with advanced production workshops, including precision casting, gravity casting, CNC machining centers, mechanical parts finishing, heat treatment, and inspection workshops. This setup en - ables us to carry out precision casting and processing on various materials, such as different grades of stainless steel, carbon steel, pig iron, ductile iron, copper, and aluminum alloys.

Stringent Quality Assurance

The ISO 9001:2015 certification and High - tech Enterprise recognition both underscore our dedication to quality. Our production process is carefully monitored, from raw material procurement to final product inspection. We've invested in sophisticated testing equipment, including component analyzers, flaw detec- tors, CMMs, and tensile testing machines. This allows us to not only meet but exceed customer require- ments regarding precision, hardness, and material composition.

Customized Solutions

Our core business focuses on producing and customizing metal parts made from carbon steel, stainless steel, aluminum alloys, copper, iron, and other materials. Our products serve a wide range of industries, including aerospace and defense, automation, construction machinery, communication equipment, auto- motive manufacturing, rail transportation, and hardware tools.

◆Rich Experience: With over 15 years in the industry, we understand the unique needs of different sectors.

◆Technical Expertise: Our team of skilled technicians and engineers can handle complex projects with ease.

◆Advanced Facilities: State - of - the - art production and testing equipment ensure top - notch quality.

◆Customization: We offer tailor - made solutions to meet the specific requirements of each customer.

◆Shenzhen Jingrui Precision Technology Co., Ltd. is dedicated to delivering high - quality products, timely services, and value - added solutions. Contact us today to explore potential collaboration and drive your business forward.

Q1: Are you trading company or manufacturer?

A1: We are a manufacturer with 19 years of production experience, welcome to visit our factory.

Q2: What's your MOQ?

Q3: What is your lead time?

A3: Stock: 5 - 10 days in general. No stock: 15 - 25 days after samples confirmed. Or please contact us by email for specific lead time base on your order quantities.

A5: Absolutely yes.

Q6: How can I get the quotation?

A6: Please send us information for quote: drawing, Amaterial, quantity or other request, we canaccept PDF, ISGS, DWG, STEP file format. If youdon't have drawing, please send the sample tous, we can quote based on your sample too.

Q7: Do you provide samples?is it free or extra?

A7: Yes, but it's not free.

A8: We can guarantee good quality, but ifhappened, please contact us immediately, take some pictures, we will check on theproblem, and solve it asap.

Q9: How to deliver the goods?

A9: We deliver the products by couriercompany.

Q10: will my drawings be safe after sendingthem to you?

A10: Yes, we will keep them well and won't release themto the third party without your permission.

A11:We willoffer a detailed production schedule and sendweekly reports with digital pic- tures and videos whichshow the machining progress.

Q12: How to enjoy the OEM services?

A12: Usually, base on your design drawings or originalsamples, we give some technical proposals and aquotation to you, after your agreement, we producefor you.