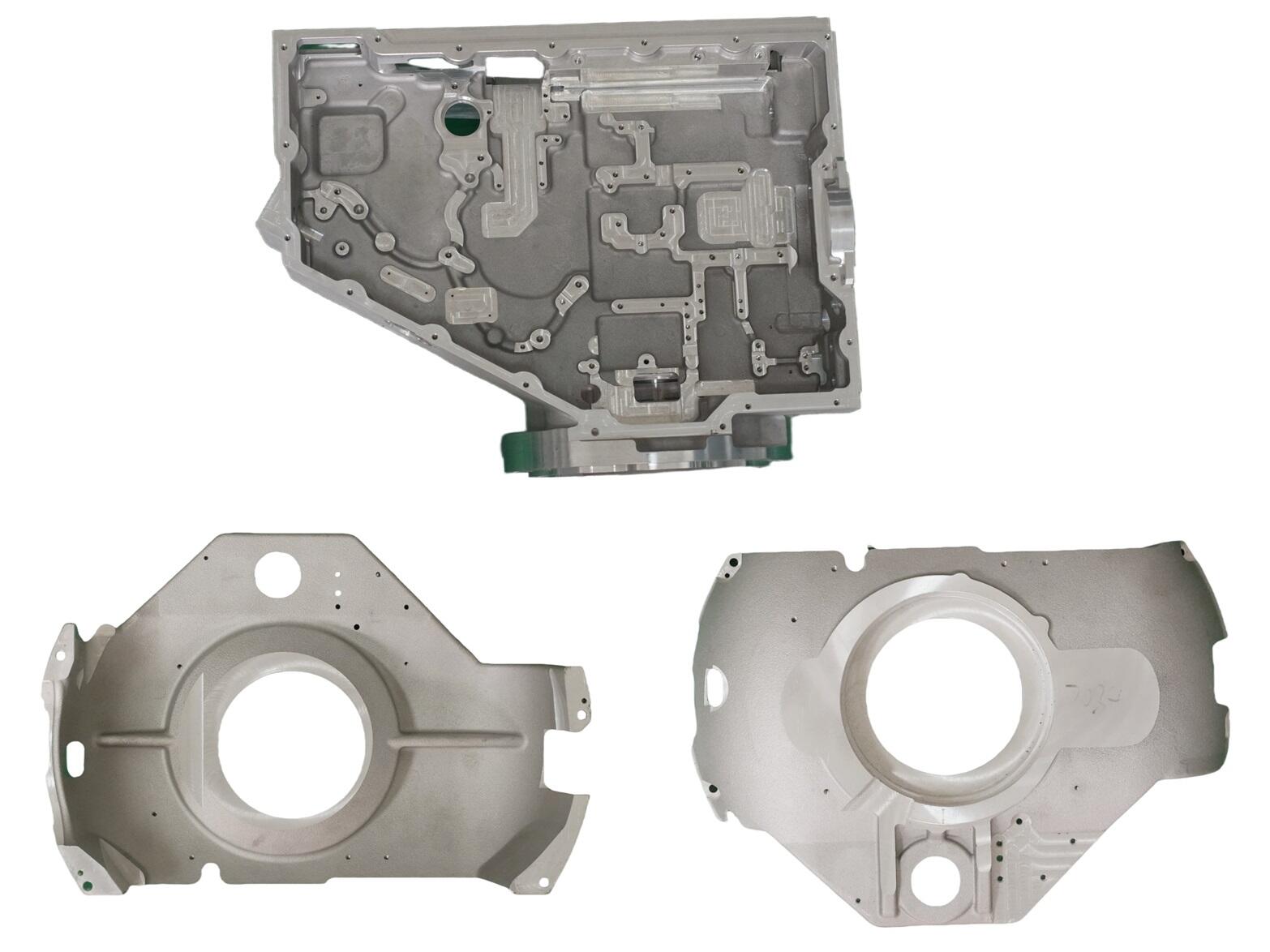

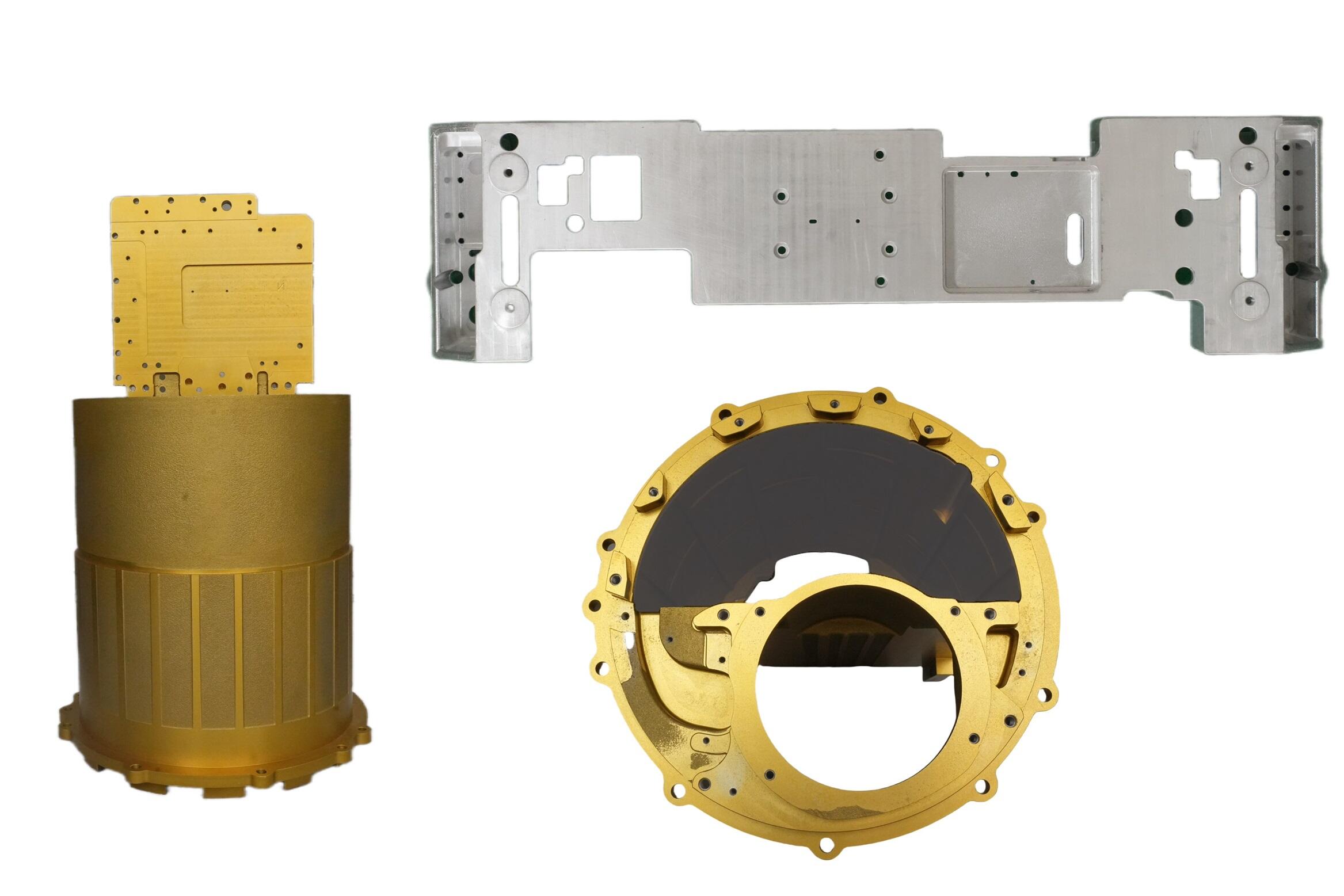

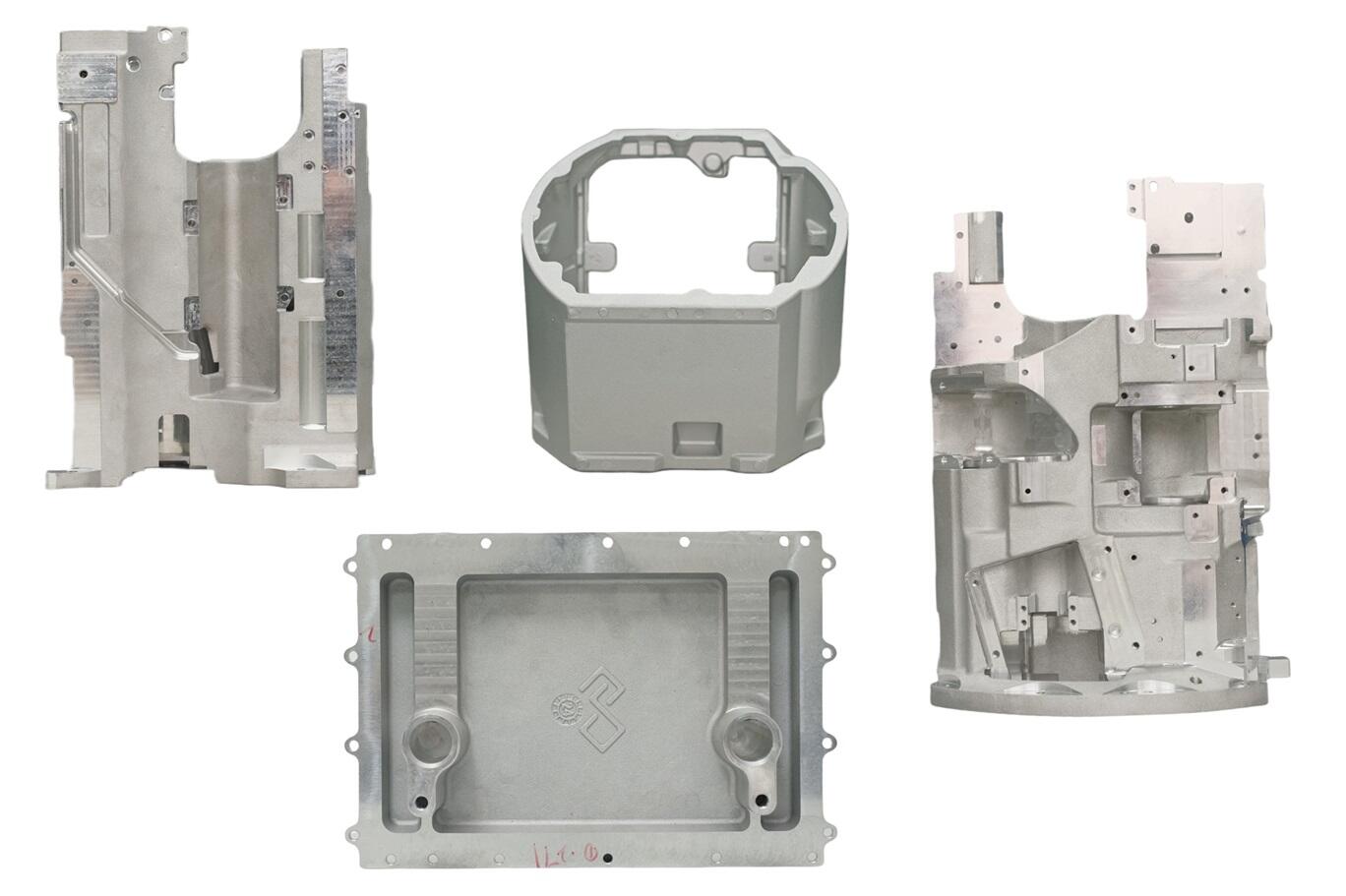

The gravity casting process is a crucial method in the manufacturing of precision metal components. At Shenzhen Jingrui Precision Technology Co., Ltd., we leverage our extensive expertise and advanced facilities to produce high-quality castings that meet the diverse needs of our clients. Gravity casting involves pouring molten metal into a mold under the influence of gravity, allowing for excellent control over the casting process. This method is particularly beneficial for producing intricate shapes and detailed designs that are often required in modern engineering applications.

Our gravity casting capabilities extend to various materials, including aluminum alloys, which are favored for their lightweight and corrosion-resistant properties. Additionally, we work with stainless steel and copper, ensuring that our products are suitable for a wide range of industries, including aerospace, automotive, and construction.

One of the key advantages of our gravity casting process is the ability to produce components with superior surface finishes and dimensional accuracy. Our ISO 9001:2015 certification reflects our commitment to maintaining high-quality standards throughout the production process. We utilize advanced testing equipment to monitor every stage, from raw material procurement to final inspection. This rigorous quality assurance ensures that our clients receive only the best products that meet their specifications.

Moreover, our experienced team of engineers and technicians is dedicated to providing customized solutions tailored to your specific requirements. Whether you need a small batch of specialized parts or large-scale production runs, we have the capacity and expertise to deliver. Our state-of-the-art production facilities, combined with our commitment to innovation and excellence, make us the ideal partner for your gravity casting needs.

At Shenzhen Jingrui Precision Technology Co., Ltd., we understand the importance of precision and reliability in your projects. Our gravity casting process not only meets but exceeds industry standards, ensuring that your components perform optimally in their intended applications. Trust us to be your partner in precision metal manufacturing, and experience the difference that our gravity casting process can make for your business.